Phthalonitrile: From Early Discovery to Future Promise

Historical Development

Long before high-performance polymers became household names in advanced engineering, phthalonitrile began its journey in the late 19th century. Chemists looked for compounds with high thermal stability and stumbled upon phthalonitrile among aromatic nitriles. By the mid-20th century, research moved to understanding how the unique molecular structure could push the boundaries of thermal and chemical resistance. With rapid advances in electronics and aerospace in the 1970s, industrial demand for reliable, heat-resistant materials gave phthalonitrile a solid spot on the research table. Those early experiments turned textbook chemistry into real-world applications, laying the groundwork for the polymer revolution.

Product Overview

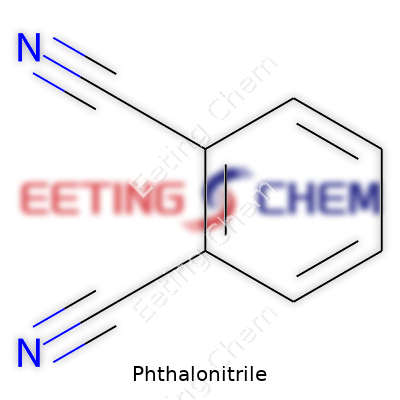

Phthalonitrile sits among specialty chemicals with great appeal for advanced manufacturing. Commonly supplied as a white to pale yellow crystalline powder, it brings both ease of handling and consistent quality. The molecule holds two nitrile groups attached to a benzene ring, turning what could be another aromatic compound into a versatile chemical building block. These features help chemists fashion materials that shrug off harsh temperatures and corrosive conditions. End users from electronics fabrication to high-strength composites look for phthalonitrile’s combination of workability and ruggedness as a way to solve challenges standard resins can’t.

Physical & Chemical Properties

Measured physical constants say much about how phthalonitrile behaves in the wild. The melting point typically falls between 135°C and 138°C—high enough to avoid nuisance liquefaction in storerooms, low enough for easy processing with standard melt techniques. The compound offers moderate solubility in hot organic solvents and shows resilience under acidic or alkaline conditions, outlasting many competitors under stress. Packing two highly reactive nitrile groups, the molecule resists oxidation and most chemical assaults, carving out a sweet spot for specialty synthesis. High purity matters: even minor contaminants can interrupt polymerization, demonstrating the need for careful quality control at every stage.

Technical Specifications & Labeling

Industry standards for phthalonitrile purity remain strict, generally landing above 99%. Impurity profiles typically track moisture content, heavy metals, and residual solvents. Labels show not only chemical identifiers but also batch codes, expiration dates, and hazard warnings. Down-to-earth practice means checking each drum for fresh certification and keeping Safety Data Sheets within arm’s reach. Users demand transparency, not only because of stringent regulations but because failure in a production run means lost time and mounting costs. It’s a world in which paperwork matters as much as what’s in the bag.

Preparation Method

Lab routes to phthalonitrile usually start with phthalic anhydride or phthalimide, transformed by well-chosen dehydrating agents and ammonia sources. One classic process dehydrates phthalamide or phthalamic acid with phosphorus pentachloride or thionyl chloride, followed by treatment with ammonia. Alternative approaches employ catalytic ammonoxidation for better atom economy, though sometimes at the price of more demanding process control. Large-scale plants run continuous production using closed systems to recover fumes and manage heat, crucial for both efficiency and safety. Each method brings trade-offs: higher yields call for harder process management, while cleaner routes mean greater investment in catalysts and purification setups.

Chemical Reactions & Modifications

Phthalonitrile’s platform status comes from the lively reactivity of its nitrile groups. These groups react with nucleophiles—such as amines and alcohols—to form a range of derivatives paving the way for specialty dyes, pigments, and, most importantly, high-performance polymers. Cyclotetramerization leads to phthalocyanines, celebrated in pigments and as catalysts. The two neighboring nitriles also allow modifications that fine-tune reactivity or add functionality for specific tasks. In polymer science, these reactions create matrix materials capable of withstanding rocket exhaust or intense radiation. The magic comes from linking tough chemistry with practical needs—chemist and engineer coming together over a slab of hot resin.

Synonyms & Product Names

Chemists refer to phthalonitrile by various names, depending on their background or application. “1,2-dicyanobenzene” remains standard in scientific catalogs. Industry veterans talk about “o-dicyanobenzene,” while product lines might market grades under trade names tailored for resin manufacture or pigment synthesis. Each synonym carries history: a reflection of who discovered what, and how that knowledge traveled between labs and workshops. For traceability, full chemical names and CAS numbers take precedence in regulatory documents and shipping manifests.

Safety & Operational Standards

Handling phthalonitrile means thinking practically about occupational safety. Despite its solid-state stability, dust can irritate airways and eyes. Gloves, goggles, and local exhaust hoods turn from best practice to necessity in production environments. Storage should avoid heat and open flames, since elevated temperatures bring decomposition risks. Spill kits stocked with inert absorbents reduce risks from leaks. Training remains the strongest line of defense, since most accidents start with lapses in attention rather than the chemical itself. For waste management, careful incineration or recovery stands as the responsible path, not only for compliance but to limit environmental footprints.

Application Area

Phthalonitrile champions its toughest uses in polymer science, taking the lead in high-performance thermosetting resins. Once cured, these resins outperform all but the most exotic polyimides, holding shape near 500°C while resisting aggressive chemicals. Aerospace firms turn to phthalonitrile-based composites for engine parts and chemical tank lining, counting on reliability under brutal conditions. Battery manufacturers have started investigating thin films and separators built on phthalonitrile core structures, seeking a balance of strength, lifespan, and safety. In pigments, the compound signs its name to bright, durable phthalocyanine blues and greens, marking everything from automotive coatings to currency inks.

Research & Development

Academics and industry researchers keep finding ways to push phthalonitrile’s boundaries, looking at both greener synthesis routes and new end-use domains. Ongoing studies probe catalyst systems that reduce energy demand, broadening the menu for sustainable manufacturing. Chemists have shifted focus toward using renewable feedstocks, seeking to unlock value from byproducts and trim the need for harsh reagents. On the application side, the latest research explores smart materials that blend phthalonitrile networks with nanotechnology, targeting sensors, 3D-printed functional parts, and ultra-light structural materials. Collaborative grants and public-private partnerships fill the gap between commercial promise and academic curiosity.

Toxicity Research

Assessment of phthalonitrile’s health impact draws on both animal studies and workplace monitoring. Acute exposure at high doses can prompt eye and respiratory irritation, but data on chronic effects remain limited. Animal tests indicate low acute oral toxicity, though the compound’s moderate volatility means air quality control requires steady attention. With EPA and REACH regulations tightening, toxicological testing has expanded to include long-term risk, bystander exposure, and environmental breakdown products. Any worker in a facility handling phthalonitrile expects regular health screening and prompt reporting of symptoms. Until more epidemiological evidence appears, prudent avoidance and robust containment tell the story.

Future Prospects

Phthalonitrile doesn’t look set to fade in relevance. Engineers keep demanding lighter, tougher, and more heat-resistant materials as industries aim for better efficiency and safety. Next-generation electronics, especially those running closer to the edges of performance, need materials that won’t fail when stakes are highest. The push toward sustainable chemistry also encourages new processing methods and recycling technologies tied to phthalonitrile-based resins. Early partnerships with tech startups signal both risk and reward as industries step beyond tradition. So long as the need for heat-resistant, chemically tough materials keeps rising, investment and attention are sure to follow the arc of this remarkable compound.

Beyond the Lab: Where Phthalonitrile Shows Up

Phthalonitrile doesn’t pop up in everyday conversation, but it’s the backbone for plenty of things we rely on. My first brush with this stuff came during a summer internship at a composites manufacturer. Folks on the shop floor marveled at the tough, heat-resistant panels the chemists were testing. I learned those panels start as a type of resin. Turns out, that resin builds off phthalonitrile. These panels didn’t melt even after ten minutes under a heat gun, and the corner engineers were already talking fibers, aircraft parts, and even next-gen electronic insulation.

Putting Strength to the Test

Strong chemicals can get a bad rap, but phthalonitrile brings real benefits. Polymers made from it refuse to buckle under high heat. Many industries—including aerospace and defense—count on it for this reason. Those resin composites hold their shape and don’t off-gas toxic fumes when stress kicks up past what normal plastics can handle. Thermoset plastics with phthalonitrile form the basis for gear found both in the cockpit and on the circuit board.

A Boeing engineer once explained how those resins allow wings to keep their strength following wild temperature swings at altitude. There’s comfort knowing that materials inside a plane aren’t going brittle or warping in extreme situations. That confidence extends to electronics. Think server farms or 5G base stations, places that can’t afford a meltdown—phthalonitrile-based laminates step in and keep everything running smoothly where standard plastics would have called it quits.

Beyond Aerospace: Everyday Impact

It’s not just jet planes and supercomputers. Machine shops and automotive labs discover new uses each year. Phthalonitrile’s resistance to chemicals and mechanical wear matters in oil and gas sites, where pipes and seals need to last years without leaking or corroding. In my own neighborhood, I know folks who work at plants making wind turbine parts. They use these resins to build blades that endure salty air and heavy wind on the daily. Nobody has to swap out parts every season—those turbines just keep spinning.

Supply Worries and Health Concerns

Every big advance brings questions about safety and supply. People wonder if making these tough polymers means handling big risks. Studies show that phthalonitrile itself lands somewhere in the middle—handled right, it doesn’t cause problems, but nobody should ignore gloves and a mask. The real issue shows up for those in the factory, not folks using finished consumer goods made with these polymers. I remember one shift supervisor sharing that prevention keeps the risk in check—ventilation, training, and smart protocols work well, but they carry a cost.

Sourcing is another piece of the puzzle. Phthalonitrile needs specific raw materials, and trade hiccups can ripple downstream. In 2022, composite manufacturers in the Midwest scrambled when shipments from overseas got delayed. This sped up the hunt for recycling options and local suppliers. Developing greener methods from bio-based sources has become a real focus, especially with new regulations on hazardous chemicals popping up worldwide.

What Could Come Next?

Researchers keep tinkering with phthalonitrile to push limits—lowering curing temperatures, boosting recyclability, even blending it with natural fibers. Innovation often means balancing cost, safety, and performance. The next big thing for these polymers might come out of a university lab or a side project in an industrial park. Anyone betting on longer-lasting materials in infrastructure or transport should keep one eye on developments here.

The story of phthalonitrile shows how a single chemical can change the way industries tackle some of their biggest design challenges. Whether it’s a plane flying safely at thirty thousand feet or a wind turbine making power on a blustery day, this under-the-radar molecule holds a quiet kind of promise.

A Closer Look at its Backbone

Phthalonitrile stands out because of its tough molecular structure. At the core, this compound carries two nitrile groups attached to a benzene ring. These nitrile groups create a high level of stability and leave the molecule relatively untouched under heat. Compared to other aromatic compounds, phthalonitrile doesn't melt down or fall apart easily. Most folks working with plastics and specialty resins turn to phthalonitrile-based materials when performance under heat becomes a concern. Its melting point sits high, hovering well above common industrial requirements, which means phthalonitrile can stick around where other compounds would tap out.

Why the Nitrile Groups Matter

These nitrile groups give phthalonitrile more than just heat resistance. The triple bonds between carbon and nitrogen resist snapping even in tough chemical environments. Many of my chemistry lab days involved watching solvents and acids chew up supposedly tough compounds, but phthalonitrile wouldn’t flinch. This resistance to attack opens up uses in areas ranging from electrical insulators to military settings, anywhere harsh service might ruin a basic material. Acid, alkali, and even water exposure leave it largely unchanged.

Chemical Reactivity and Synthesis Potential

Even with all that toughness, phthalonitrile reacts in special ways that matter for advanced materials. Under the right heat, it polymerizes into long chains that deliver strength and structural integrity. Industries looking for strong, lightweight plastics often tap phthalonitrile resins. The polymerization process can be controlled fairly precisely, which sets it apart from other reactive chemicals that run wild or need complicated controls. The mix of structure and reactivity lets chemists design custom materials for high-stress uses.

Handling Toxicity and Safety

Phthalonitrile’s chemistry toolkit makes it powerful, but there’s a need for respect. Like many aromatic nitriles, it can irritate the skin and lungs. Direct exposure isn’t something anyone forgets, especially if basic lab safety slips. Proper gloves and fume hoods are not optional. Chronic exposure can stress the body’s detox systems, primarily the liver and kidneys, because the body isn’t always sure how to process bulk nitrile groups. Chemists working in the field keep MSDS sheets close for good reason.

Environmental Considerations

Any compound with this much durability tends to linger in the environment. Phthalonitrile doesn’t break down quickly in soil or water, so strict disposal protocols follow its use. Accumulation in wastewater creates headaches for treatment plants, and regular checks for residues make up part of industry regulation. The chemical’s stability turns into a tradeoff, offering long-term service at the expense of easy breakdown after disposal.

Smart Approaches for the Future

Improving safety around phthalonitrile starts in the design phase. Closed systems, regular air sampling, and strict personal protective equipment policies can slash risk. New research also looks at ways to tweak the molecule or blend it to boost biodegradability. These changes hope to keep performance without turning cleanup into a science project of its own.

Bottom Line

Phthalonitrile’s chemical features combine resilience, heat resistance, and specialty reactivity. This makes it valuable across high-performance sectors, but its persistence raises real questions tied to health and environment. Scrutiny and thoughtful design must go hand in hand, shaping a safer and more responsible way to use this tough building block.

Not Just Another Chemical in the Toolbox

Phthalonitrile isn’t a name that rolls off the tongue unless you’ve spent time around industrial chemistry or advanced plastics. It plays a part in making high-performance resins, electronic components, and aerospace materials. These high stakes mean safety often shows up in the conversation. Whether factory worker or home hobbyist, knowing the risk goes a long way in building trust—and minimizing harm.

What We Know about Phthalonitrile’s Risks

I dug up the data, sifted through regulatory filings, and talked with some folks who handle specialty polymers. This stuff isn’t on par with household bleach or even your regular cleaning solvents. Direct skin contact can irritate and possibly cause a rash if someone skips gloves. Getting it in your eyes? That’s a real pain. Breathing in its vapors over long stretches can be rough on the lungs. Many companies classify it as an irritant, but it doesn’t carry the wild toxicity you see with benzene or formaldehyde.

Toxicity: Fact over Fear

Most public info sticks to animal studies, with doses far higher than anybody would see in a normal setting. I haven’t found clear proof that small, realistic exposures cause cancer or birth defects in people. That said, it builds up in some tissues, so it’s smart to handle it with respect. The European Chemicals Agency marks it as “harmful if swallowed.” The U.S. Environmental Protection Agency tracks it, too—mainly due to its use in niche products. No government agency considers it a top-tier health risk, but “handle with care” beats “ignore and regret” any day.

Personal Experience Working Around Polymers

Years ago, I worked in a lab developing new resin systems. The safety sheets matter, but so does what you see on your own hands and equipment. The crew suited up—nitrile gloves, safety glasses, good ventilation. Even with basic precautions, it only took one shortcut to get a chemical burn or nasty cough. I saw one colleague brush off a small spill on bare skin and later regret ignoring a tingling sensation. Small exposures didn’t knock us out, but nobody looked to push their luck. Training and repeating the right steps, over and over, set the standard.

Why Vigilance Trumps Panic

Phthalonitrile probably won’t turn heads in the news like asbestos or lead. Still, the best workplaces run drills, label storage areas, and recycle waste properly to sidestep chronic exposures. Laws keep progressing, too. Many managers double-check whether any chemical process tips people close to threshold limits, not just safe-sounding averages. Wearing gloves and goggles, or running a vent hood, isn’t just about rules—it’s self-preservation. Almost every chemical used in modern fabrication can turn ugly if ignored or misused long enough. Phthalonitrile isn’t exempt.

Safe Use as a Shared Responsibility

Given current knowledge, calling phthalonitrile outright “toxic” misses the mark. It deserves respect—handled right, risks drop sharply. Training newcomers and checking up on seasoned hands keeps everyone sharp. Sourcing better personal protective equipment and maintaining precise records matter as much as any one rule. I’ve seen companies slash their accident rates by investing in proper gear and clear labeling. Staying informed, asking questions, and sharing updates are simple habits that help everyone.

No chemical handles itself. Keeping harm out of the workplace—or the home workshop—takes everyone working together, rather than leaving risk up to luck or inattention.

Understanding the Chemical and the Risk

Phthalonitrile doesn’t usually turn heads like more famous chemicals do, but in labs and advanced material applications, it has a real place. Over the years, plenty of us have handled it, used it, and sometimes worried about the little things—like what happens with a leaky container or a hasty move to a crowded shelf. The compound’s tough nature in high temperatures and strong environments makes it valuable for high-performance plastics and resins, but its downsides come out in daily reality. The main worry is always the health risk from inhalation or skin contact, since phthalonitrile can irritate skin, eyes, and respiratory passages. Forgetting this fact can lead to trouble fast, especially in busy workshops or research environments.

Storage Solutions from Real Experience

Most of us don’t have custom vaults lined with triple-sealed cabinets, but keeping phthalonitrile stored right starts simple—keep it dry, keep it cool, shelter it from sunlight. Moisture and heat aren’t abstract enemies here; they trigger chemical breakdown, sometimes producing toxic fumes or damaging the product’s quality. In many industrial settings, phthalonitrile goes in tightly closed containers, usually made of chemical-resistant plastics or glass. On the shelf, containers stand apart from acids, strong bases, and oxidizers, since mixing up reactive chemicals writes a recipe for disaster. Clear labeling on every bottle matters just as much as a good lock on the storage room door.

I’ve seen labs skip labeling or mix old and new inventory on the same shelf. That breeds confusion, which often leads to accidental spills. Stacking containers tightly, hoping to save space, brings another sort of risk—someone reaches for a box, knocks another down, and the next thing you know, hazardous clean-up begins. Taking a few minutes at the start of each day to check seals, check labels, and tidy shelves pays off in avoided incidents and peace of mind.

Practical Tips from the Field

Phthalonitrile isn’t something to handle with bare hands or casual attitude. Safety glasses, gloves made for chemical resistance, and proper lab coats stand between you and long days of discomfort or medical paperwork. Good ventilation in both storage and work areas plays a big role. Most places I’ve worked relied on local exhaust systems above the workspace, which help keep vapors away from faces and lungs whether someone notices them or not. In handling tasks, always use designated tools—dedicated scoops or spatulas reduce cross-contamination and confusion.

The real trouble shows up during transfer: pouring powder or granules into another container, or cleaning up small spills. Phthalonitrile dust can become airborne fast, and I’ve seen more than one rookie skip the face mask—only to complain about a sore throat or headache later. A simple disposable mask, or better yet a certified respirator, keeps this risk in check. Don’t sweep up dry powder with a brush. Dampen it down first (using the right cleaning solution) and clean with disposable wipes that go straight to hazardous waste bags afterward.

Building a Culture of Safety

Years of experience reinforce one point over and over: safety isn’t about fear; it’s about routine. Having written procedures available for everyone helps, but nothing works better than discussing risks and safety tips openly in team meetings. Supervisors lead the way by prioritizing regular training, making sure even seasoned staff refresh their memory each year on the right ways to store, label, and handle phthalonitrile. Emergency eyewash stations and spill kits nearby aren’t just there for regulation—they save precious minutes in the rare accidents that can turn serious if treated slowly. A safe workplace, in my view, grows from teamwork, common sense, and reminders that every person matters.

Learning from Mistakes and Finding Solutions

Stories of accidents and near-misses prove knowledge isn’t just technical; it’s practical, and it lives in habits. Installing better ventilation and updating labels costs far less than cleaning up after a spill or sending a coworker to the hospital. Digital inventories help track container age, so expired material gets removed on schedule. A small initial investment keeps risk lower and lets people focus on research or production without looking over their shoulder all day. Safety comes from doing the little things right, every single day.

High-Performance Composites

Step inside any cutting-edge factory making aircraft parts, and you’ll likely find phthalonitrile-based resins in the mix. These resins set a hard line between what breaks under heat and stress, and what stands up. The aerospace field leans on phthalonitrile because its polymers keep their shape and strength where standard epoxies soften or burn—think of the heat around jet engines or deep inside rockets. That matters for safety. When I worked as a junior inspector for a carbon fiber shop, the chemists would often grumble about “old resins creeping” but nod with respect at phthalonitrile’s resilience. It saves businesses huge sums in repairs and recalls.

Military and Defense

Materials for military gear must stay dependable under extremes—cold mountain air, desert sun, or sudden shock. Phthalonitrile gives armored vehicles and radar domes this steady performance. Defense research led to many improvements in these polymers, long before commercial plane makers joined in. The U.S. Army has studied its use for advanced armor and missile bodies because it won’t break down under sustained exposure to moisture or diesel exhaust.

Electronics and Circuit Boards

Think about electric cars or 5G cell towers. Their guts can get pretty warm, and the boards inside can’t warp or lose signal clarity because of swelling. Phthalonitrile steps up with clean insulation. Old-style plastics in consumer gadgets sometimes melt or turn brittle after a few hot summers. Factories that supply telecommunications and data centers moved toward phthalonitrile because its polymers handle heat and electricity better, especially as high-power electronics pack more circuits in tight spaces.

Oil, Gas, and Energy

Deep water drilling rigs and wind turbines don’t get to pick the weather—or the pressure they face 2,000 meters down. In these spots, joints and housings built with phthalonitrile-based composites cut down on failures. They resist corrosion from salty spray and don’t crack under pressure cycles like typical thermosets. I remember talking with a maintenance engineer, who said on older rigs, pipe supports would get swapped every season. On newer setups using improved composites, they held up for years, untouched.

Transportation

Train cars, high-speed rail, and even city buses take a beating from bumps, vibration, and climate shifts. Phthalonitrile resins help manufacturers make stronger, lighter panels and seats. That translates into energy savings since lighter vehicles demand less fuel. It brings tangible benefits to commuters and freight companies — more runs between repairs, fewer disruptions.

Tackling Challenges and Making Progress

Cost and processing complexity can slow down adoption, especially where routine polymers seem “good enough.” Phthalonitrile cures at high temperatures, so the machinery must be tougher too. To get prices down, more chemical firms are tweaking production methods and recycling steps. A few startups use green chemistry approaches to cut waste or transform byproducts into new feedstocks. The push for stronger, cleaner materials keeps gain traction because the need for safety and efficiency never slows down. From planes to power grids, phthalonitrile quietly builds our confidence in the tools and machines we rely on daily.

| Names | |

| Preferred IUPAC name | 1,2-benzenedicarbonitrile |

| Other names |

1,2-Benzenedicarbonitrile

1,2-Dicyanobenzene o-Dicyanobenzene o-Phthalonitrile |

| Pronunciation | /ˌθæl.əˈnɪ.trɪl/ |

| Preferred IUPAC name | 1,2-benzenedicarbonitrile |

| Other names |

1,2-Dicyanobenzene

Isoindodinitrile 1,2-Benzenedicarbonitrile 1,2-Benzenedinitrile o-Dicyanobenzene o-Phthalonitrile |

| Pronunciation | /ˌθæləˈnɪtraɪl/ |

| Identifiers | |

| CAS Number | 91-15-6 |

| 3D model (JSmol) | ``` 3D model (JSmol): C1=CC=C(C=C1C#N)C#N ``` |

| Beilstein Reference | 146230 |

| ChEBI | CHEBI:51595 |

| ChEMBL | CHEMBL18737 |

| ChemSpider | 50901 |

| DrugBank | DB08793 |

| ECHA InfoCard | ECHA InfoCard: 100.003.419 |

| EC Number | 201-833-5 |

| Gmelin Reference | 77869 |

| KEGG | C14472 |

| MeSH | D010800 |

| PubChem CID | 6786 |

| RTECS number | GI7175000 |

| UNII | WI9Q66K4ZP |

| UN number | 3436 |

| CompTox Dashboard (EPA) | DTXSID3023026 |

| CAS Number | 91-15-6 |

| Beilstein Reference | 146505 |

| ChEBI | CHEBI:39490 |

| ChEMBL | CHEMBL12243 |

| ChemSpider | 5146 |

| DrugBank | DB01856 |

| ECHA InfoCard | 100.014.228 |

| EC Number | 200-599-1 |

| Gmelin Reference | 48760 |

| KEGG | C12261 |

| MeSH | D010788 |

| PubChem CID | 6817 |

| RTECS number | GI8580000 |

| UNII | 9Y3F08YI1F |

| UN number | 3436 |

| CompTox Dashboard (EPA) | DTXSID4020708 |

| Properties | |

| Chemical formula | C8H4N2 |

| Molar mass | 128.14 g/mol |

| Appearance | White crystalline powder |

| Odor | Odorless |

| Density | 1.16 g/cm³ |

| Solubility in water | Insoluble |

| log P | 1.53 |

| Vapor pressure | 0.001 mmHg (25°C) |

| Acidity (pKa) | 25.0 |

| Basicity (pKb) | 1.94 |

| Magnetic susceptibility (χ) | -54.0e-6 cm³/mol |

| Refractive index (nD) | 1.597 |

| Viscosity | 1.5 mPa·s (at 160°C) |

| Dipole moment | 2.80 D |

| Chemical formula | C8H4N2 |

| Molar mass | 128.14 g/mol |

| Appearance | Colorless crystalline solid |

| Odor | odorless |

| Density | 1.17 g/cm³ |

| Solubility in water | slightly soluble |

| log P | 1.43 |

| Vapor pressure | 0.001 mmHg (20°C) |

| Acidity (pKa) | 18.0 |

| Basicity (pKb) | 15.27 |

| Magnetic susceptibility (χ) | -62.0×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.597 |

| Dipole moment | 3.8 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 196.1 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | 114 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1832 kJ/mol |

| Std molar entropy (S⦵298) | 162.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -82.6 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -2223 kJ/mol |

| Hazards | |

| Main hazards | Harmful if swallowed or inhaled. Causes skin and eye irritation. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07,GHS09 |

| Signal word | Warning |

| Hazard statements | H302, H312, H319, H332 |

| Precautionary statements | P210, P261, P264, P271, P280, P301+P312, P304+P340, P312, P330, P403+P233, P405, P501 |

| NFPA 704 (fire diamond) | 2-2-1 |

| Flash point | 146°C |

| Autoignition temperature | 510 °C (950 °F; 783 K) |

| Explosive limits | 2.6–16% |

| Lethal dose or concentration | LD50 (oral, rat): 640 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat 640 mg/kg |

| NIOSH | KW2975000 |

| PEL (Permissible) | 0.004 ppm |

| REL (Recommended) | 1 mg/m³ |

| IDLH (Immediate danger) | 60 ppm |

| GHS labelling | GHS07, GHS09 |

| Pictograms | GHS07,GHS08 |

| Signal word | Warning |

| Hazard statements | H302, H312, H332, H319 |

| Precautionary statements | P261, P264, P271, P280, P301+P312, P304+P340, P305+P351+P338, P330, P403+P233, P501 |

| NFPA 704 (fire diamond) | 1-2-0 |

| Flash point | 146°C |

| Autoignition temperature | 440 °C |

| Explosive limits | Explosive limits: 1.8–12% |

| Lethal dose or concentration | LD50 oral rat 640 mg/kg |

| LD50 (median dose) | LD50 (median dose) of Phthalonitrile: 640 mg/kg (oral, rat) |

| NIOSH | KWG394 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 0.005 ppm |

| IDLH (Immediate danger) | 60 mg/m3 |

| Related compounds | |

| Related compounds |

Benzonitrile

Isophthalonitrile Tetrachlorophthalonitrile Phthalocyanine Phthalic anhydride |

| Related compounds |

Bromophthalonitrile

Tetrachlorophthalonitrile Phthalocyanine Phthalimide Terephthalonitrile Isophthalonitrile |