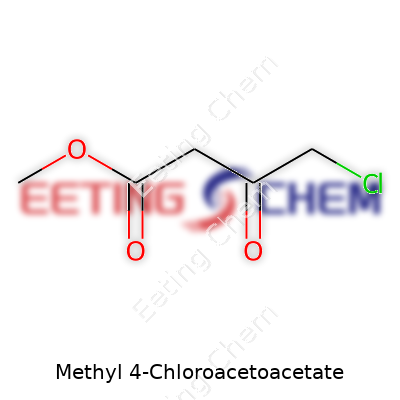

Methyl 4-Chloroacetoacetate: A Commentary on Its Journey, Properties, and Impact

Historical Development

Chemists began exploring Methyl 4-Chloroacetoacetate as early as the mid-20th century, running with the big push toward new synthetic building blocks that supported a swelling pharmaceutical industry. Researchers carved out a chunk of the acetoacetate field for themselves, looking for functionalized derivatives such as the 4-chloro version that would open doors to more complex molecules. Interest picked up as people realized its flexibility, both in labs and in industrial-scale settings, matched the rising demand for efficient chemical intermediates. Not just academic pride swung the spotlight onto this compound. Manufacturers saw real-world demand, so they honed cost-effective and cleaner routes, leaving their mark on commercial processes.

Product Overview

Known as Methyl 4-Chloroacetoacetate, this molecule’s usefulness stretches far beyond a simple entry in a catalog. Its core features a methyl ester group and a reactive chlorine, letting it slide easily into a variety of chemical reactions. It winds up as raw material for pharmaceuticals, agrochemicals, and specialty chemicals. The chemical community prizes it for the blend of reactivity and stability—balanced enough to store and handle for some time, but reactive enough to take part in creative organic synthesis. This balance means process chemists keep returning to it for triggers in multi-step routes.

Physical & Chemical Properties

You can spot Methyl 4-Chloroacetoacetate by its pale, often colorless liquid form. It gives off a distinctive, sharp odor. The molecular weight reads around 166 grams per mole. With a boiling point usually clocking in around 200°C or so, and a melting point low on the spectrum, it resists solidification in most labs. Its solubility leans towards organic solvents; it mixes easily with ether and alcohol, refusing to dissolve fully in water. Chemically, the 4-chloro and the beta-keto-ester functionalities set it up for nucleophilic substitution, enolate formation, and condensation reactions with various partners, making it a staple for folks who enjoy a bit of chemical handiwork.

Technical Specifications & Labeling

Suppliers list the minimum assay at over 98%, tracking water content, residual solvents, and acids to ensure material behaves predictably in the field. Labels carry essential hazard notations, including pictograms for acute toxicity and environmental warnings due to its halogen content. Details usually cover the molecular formula (C5H7ClO3), batch numbers, and storage guidance, including suggestions for cool, dry, well-ventilated storage. Regulatory compliance follows GHS labeling standards and relevant transport codes. Well-maintained records between sellers and buyers ensure accountability for safe handling through the life cycle of the chemical.

Preparation Method

Production of Methyl 4-Chloroacetoacetate rides on established protocols. The route often begins with chloroacetic acid and methyl acetoacetate, subjecting the combination to acid or base catalysis. Chlorination at the appropriate stage introduces the 4-chloro group, sometimes using direct chlorination methods if purity holds up and yield remains high. Industrial players optimize these reactions to suppress by-products and favor the target compound. Green chemistry pushes more labs to scale down solvent waste and temperature extremes, inching closer to sustainable synthesis without giving up on efficiency.

Chemical Reactions & Modifications

As a beta-ketoester with a 4-chloro handle, this molecule jumps into alkylation, condensation, cyclization, and nucleophilic substitution. Pharmaceutical R&D depends on such chemistry for building rings or fusing heterocycles needed in active drug components. Modifying the ester or replacing the chlorine with nucleophiles generates libraries of analogs for screening. Enolate chemistry lets scientists stitch together larger molecular frameworks, sometimes using this compound as a linchpin in multistep syntheses. Its reactivity offers shortcuts that would otherwise call for clunky protection and deprotection steps.

Synonyms & Product Names

Try looking for Methyl 4-Chloroacetoacetate under different labels: 4-Chloroacetoacetic acid methyl ester, Methyl 4-chloro-3-oxobutanoate, or simply MCA. Suppliers sometimes abbreviate or use the IUPAC tag, making it essential for buyers to chase the right specification rather than just a name. Documentation sticks to CAS number 56051-04-0 to sidestep confusion, which helps industry veterans and newcomers link up global standards and inventories.

Safety & Operational Standards

Direct skin contact and inhalation carry health risks, including irritation, systemic toxicity, and respiratory trouble. Staff gear up with gloves, goggles, and face shields, running transfers in fume hoods and ventilated spaces whenever possible. Standard operating procedures lock in spill response and cleanup, with waste routing into approved hazardous streams. Fire safety plans call for foam, CO2, or dry chemical extinguishers due to the risk of exothermic decomposition under high heat. Emergency protocols must stay current, built around real incident reports and hazard assessments. Training—regular as clockwork—equips workers to spot early signs of exposure or mishandling, reducing incidents.

Application Area

Drug and pesticide development counts on Methyl 4-Chloroacetoacetate for building complex scaffolds, many times as a core step in multi-ring pharmaceuticals or herbicides that demand fine-tuned side chains. Specialty coatings, fragrances, and even pigment manufacturers draw on its chemistry for tailored molecular features. Research outfits keep it in stock for exploring analog synthesis, structure-activity relationships, and probing the edges of organic chemistry. Its presence pops up in both finished products and intermediates, giving it longevity in supply chains despite shifting market trends.

Research & Development

Investments in speedier, environmentally friendlier manufacturing stack up year after year. Automation enters lab and plant floors, shortening turnaround for new reaction screening and optimization. Academic teams target higher atom economy and seek alternatives to halogenated waste, recognizing that regulatory and sustainability pressures show no signs of letting up. Collaboration between universities, startups, and large manufacturers has started bridging the gap, bringing safer and more adaptable production online. Real-time analytics and machine learning show promising gains in predicting reaction outcomes, meaning less guesswork and fewer failed batches.

Toxicity Research

Toxicologists have looked closely at Methyl 4-Chloroacetoacetate, finding acute toxicity via ingestion or inhalation, with animal models backing up the need for strict exposure limits. Skin and eye contact produces irritation, with systemic effects possible with prolonged or repeated contact. Environmental impact studies show that halogenated ester waste persists, affecting water and soil health. Regulators demand comprehensive dossiers before letting manufacturers ramp up output, with special focus on disposal and mitigation measures. Ongoing research digs deeper into chronic effects and better personal protective measures for workers.

Future Prospects

Industry trends push for lower environmental impact in both the manufacturing and disposal phases. Scientists put forward catalytic and biocatalytic transformation techniques, banking on enzymes to reduce hazardous by-products. Digital tools guide synthetic planning for lower waste and resource use. Investors and regulatory bodies nudge manufacturers to phase in renewables and recyclable materials, so new routes and feedstocks remain in focus. As new synthetic methodologies emerge, the role of Methyl 4-Chloroacetoacetate won’t fade; instead, it could take on wider utility, backed by stronger safety data and cleaner processes.

Understanding the Basics

Methyl 4-chloroacetoacetate brings together both organic chemistry and practical chemistry lab life. Its chemical formula is C5H7ClO3. This compound features a methyl ester at one end, a ketone group in the middle, and a chlorine atom on the fourth carbon. If you’ve ever tried to read a bottle label in the lab or search for reagents online, this formula acts as a kind of shorthand for what you’re about to handle. Safety data, regulatory filings, even purchase orders all depend on this precise arrangement of atoms.

The Role in Organic Synthesis

You can’t talk about this molecule without bringing up its spot in medicinal and agrochemical development. Methyl 4-chloroacetoacetate serves as a vital building block. Synthetic chemists appreciate its structure because it opens doors for all sorts of reactions—alkylations, condensations, cyclizations. In simpler terms, linking these pieces lets a researcher build complex molecules faster and more efficiently. For anyone who has spent late nights running columns in graduate school, streamlining a multi-step synthesis means you go home a bit earlier and waste fewer chemicals along the way.

Why the Formula Matters in Real Life

Getting the chemical formula wrong causes a cascade of problems. I remember back in my university days; an incorrect entry for a similar compound delayed our order by a week. The supplier couldn't verify the shipment, and the wrong shipment almost ended up in the fume hood. Accurate formulas keep chemists, lab techs, and logistic teams on the same page, especially given regulatory oversight and hazardous substance management rules. The Environmental Protection Agency and similar organizations look for precise information to prevent accidents or environmental mishaps.

Health and Environmental Considerations

This compound, like many with halogenated and carbonyl groups, needs careful attention. Inhaling or incorrectly handling chemicals like this isn’t a badge of honor in the lab—it’s an unnecessary risk. Safety data sheets always mention wearing gloves, avoiding spills, and using fume hoods. After seeing a minor spill corrode a benchtop, I never forgot to double-check storage containers and keep spill kits nearby. The formula doesn’t just guide the synthesis; it shapes the way researchers set up their workspaces to protect both themselves and the planet.

Encouraging Responsible Handling

Schools can help by hammering home the dose of respect these chemicals deserve from the first day students walk into a lab. Seasoned professionals need refresher training, too. Companies benefit when everyone knows how to read formulas and translate them into real-world safety and compliance. Chemical manufacturers could invest more in clear labeling and digital resources to cut down errors and hazardous incidents. Labs can adopt better digital inventory systems that flag when a dangerous reagent sits too close to an incompatible compound. Choices like these have saved research budgets and protected lives in labs small and large.

A Key Link in Pharmaceuticals

Methyl 4-chloroacetoacetate stands out in synthetic chemistry because it drives critical steps in making active pharmaceutical ingredients. Industry insiders turn to this compound when crafting building blocks for drugs—especially those that rely on the acetoacetate structure to connect different molecular groups together. Antibiotics, fungicides, and even antivirals benefit from its chemical hooks. The presence of both a reactive chloro group and a ketoester backbone helps chemists splice together complex molecules, cutting down on time and waste in the lab.

Think about drugs for cardiovascular disease or antibacterials targeting infections. Research teams at biotech companies often use methyl 4-chloroacetoacetate to create intermediate substances, paving the way for more effective treatments. Their choices matter because the demand for custom medicines keeps surging, and every shortcut in synthesis can translate into faster access for patients who need life-saving therapies.

Crop Protection and Pesticides

Outside the lab, farmers keep food growing year-round, relying on modern pesticides to cut back on losses. Methyl 4-chloroacetoacetate often takes a backstage role in the creation of crop-protection agents. Agrochemical manufacturers favor it because the molecule acts as a starting scaffold for fungicides and herbicides. Its properties help stabilize active ingredients, making products more dependable through storage and application.

Corn, wheat, and rice fields worldwide depend on better chemicals to fend off blight, mildew, and weeds. Chemical engineers know that using methyl 4-chloroacetoacetate gives them a way to fine-tune active outputs, leading to targeted pest management. This approach reduces waste in the field and can cut back on the volume of product farmers use, a win for environmental stewardship and cost control.

Dyes and Pigments

The reach of methyl 4-chloroacetoacetate goes beyond health and agriculture. It quietly supports the pigments industry, showing up in the synthesis of dyes for textiles, plastics, and inks. Chemists depend on the molecule’s versatility: by attaching different groups to its reactive sections, they unlock novel color shades or improve the staying power of dyes under heat and light.

In my early days in a textile firm, our technical lead prized stability and vividness of color. If the dye didn’t stick through repeated washes, it cost customers money. New pigment blends based on robust intermediates like methyl 4-chloroacetoacetate gave us an edge. Factories turning out clothing or product packaging don’t often realize the cascade of specialized chemistry running behind the scenes, yet it shapes the colors and branding we encounter every day.

Challenges and Solutions to Safer Use

Handling methyl 4-chloroacetoacetate requires solid safety steps because its reactivity means risks in storage, shipping, and handling. Chemists must wear appropriate gear, ventilate their workspaces, and track inventory to prevent accidents. It’s not just about regulations—workplace injuries and hazardous spills can bring production lines to a halt and lead to hefty fines.

Industry can do more by investing in closed-system transfers and finding catalysts or green solvents that lower the process temperature, which can cut energy use and emissions. The move toward cleaner manufacturing in recent years reflects growing pressure from customers, investors, and policymakers to reduce pollution, save energy, and treat workers right. Tougher oversight might seem like a burden, but safer protocols pay off in uptime, quality, and reputation.

Looking Ahead: Constant Demand for Smart Chemistry

The story of methyl 4-chloroacetoacetate offers a glimpse into how small ingredients can drive big changes. Its fingerprints show up in pills, food, and the colors all around us, making it a quiet driver of modern convenience and well-being. Strong stewardship, from better safety to smarter process design, will only grow in importance as chemical needs increase and regulations tighten.

Unpacking the Real-World Risk

Methyl 4-chloroacetoacetate gets used in everything from pharmaceuticals to specialty chemicals. It looks like a simple liquid, but experience in the lab tells a different story. I’ve seen what happens when bottles of solvents or reactive organics sit too long on a shelf in the wrong place—sticky caps, off smells, and an unplanned safety drill. The thing about methyl 4-chloroacetoacetate is that it isn’t the most volatile compound, but it still carries risks. Eye and skin irritation, and a nasty kick if you breathe the vapors too long, mean it deserves respect. Here’s what knowledge and practice tell us about how to treat it right.

Why Cool, Dry, Ventilated Spaces Matter

Methyl 4-chloroacetoacetate performs best in a cool and dry spot, away from strong sunlight. High room temperature means higher vapor pressure, which increases not only smell but also risk of inhalation—an easily avoided hazard. Damp storage areas bring their own issues. Water might not break this ester down immediately, but humidity invites hydrolysis over time, messing with purity and consistency. I remember a colleague pulling an old bottle from above a steam radiator—contents had started to crystallize, and nobody wanted to guess what was actually inside.

The Need for Secure Containers

Not every bottle seals the same way. Screw-tops without gasketed seals often let air in, raising worries about degradation or unwanted reactions. Laboratory experience taught me early that labeling dates and checking seals each use saves trouble later. Amber glass often beats plastic. Glass resists the tendency of this chemical to soften or leach through less robust plastics, while a dark bottle keeps stray light off sensitive compounds. Our own inventory never has these bottles in clear plastic on an open shelf; that’s asking for contamination from light or leaks.

Avoid the Wrong Neighbors

Proper segregation prevents easy mistakes. Acids and bases don’t belong nearby. Even with a closed cap, vapors or tiny spills can create unexpected problems. I’ve seen shared chemical cabinets where bottles of oxidizers sit right next to organics like methyl 4-chloroacetoacetate—one spill or breakage and you’ve got a bigger problem than just a waste run. Flammable liquids need their own space.

Real-World Spill Prevention

Spill trays and secondary containment aren’t just box-ticking paperwork. They’re life-savers for those times the cap’s loose or a jug tips as someone rushes at the end of a shift. Stories from busy labs remind us that accidental mixing from old or unlabeled material has led to incidents that could have been avoided with the right storage.

Regulation and Health Perspective

Occupational safety agencies like OSHA stress the use of tight containers, proper labeling, and isolated chemical storage for good reason. Exposure limits exist for compounds like methyl 4-chloroacetoacetate, which has shown health effects in animal studies and documented cases. Good storage cuts down on risk—from immediate exposure to the headache of disposal after a product’s gone bad. Hospitals and fire codes set rules on how much can be kept and where, and for researchers and industry these rules are the baseline, not a luxury.

Building Responsible Practice

No daily operation runs on autopilot. Staff should walk storage areas, check for bottle condition, clean up spills right away, and make sure that what’s inside every bottle matches what’s marked on the label. Practical experience paired with solid chemistry knowledge makes for a safer workspace and less waste. Attention pays off not just for your health, but for everyone handling the chemical down the line. That’s what builds a culture of trust and safety in science—day by day and bottle by bottle.

Real Risks Behind a Common Chemical

Folks working in pharmaceuticals or fine chemicals may notice methyl 4-chloroacetoacetate on more than one materials list. This compound, with its simplicity, pops up in labs and factories, often shipped in drums with hazard labels. So, it makes sense to ask: is methyl 4-chloroacetoacetate hazardous or toxic?

How Methyl 4-Chloroacetoacetate Behaves

The chemical formula—C5H7ClO3—only tells part of the story. In a real-world setting, this stuff proves volatile. Fumes build up during handling. Any small leak can clear out a lab in minutes. Inhalation brings headaches, breathing issues, and irritation in the eyes, nose, and throat. Many lab workers, on their first encounter, describe a sharp, biting aroma that lingers in the air and on clothes.

Reading safety data sheets from manufacturers or global agencies like the European Chemicals Agency always brings warnings up front. Direct contact with skin causes burns or blisters, and splashes in the eyes risk lasting damage. Most folks across the chemical industry wear gloves and face shields for a reason, and this compound helps explain why.

Toxicity: Data and Experience

Acute toxicity numbers, like LD50 in rats or rabbits, tell us the lethal dose sits at relatively low exposures. Animal studies show damage to organs over time when exposure becomes routine. Chronic effects can creep up. Folks might feel fatigue or dizziness working with methyl 4-chloroacetoacetate in poorly ventilated spaces. I remember a plant manager telling stories of mild poisoning symptoms from a minor spill that left a worker queasy for days.

Accidental mixing or heating triggers dangerous reactions, sometimes producing corrosive fumes. These not only smell awful but can choke up a whole building. As someone who’s worked in process scale-ups, I’ve seen first-hand how small calculation errors with volatile chemicals like this produce sudden emergencies. Quick drenching showers, evacuation drills, and routine spill training stay fresh for anyone working near these labs.

Safer Handling Practices

So what helps? Ventilation systems with good local exhaust make the biggest difference. I’ve watched teams reduce exposure rates nearly to zero after swapping open beakers for sealed, ventilated vessels. Protective gear—nitrile gloves, goggles, lab coats—should never be a step folks skip out of hurry. Storing the chemical in tightly sealed containers, far from acids or reducing agents, prevents mishaps during unexpected temperature swings or line failures.

Emergency stations, from eyewash fountains to chemical showers, work best when they’re easy to reach and free from clutter. Workers benefit from real training: not just reading manuals but walking through emergency scenarios, understanding what happens during a spill, and feeling comfortable reporting near misses.

Looking Forward

Better practices, reliable PPE, and smart engineering controls will help keep methyl 4-chloroacetoacetate in check. Some companies move to less hazardous alternatives, but process needs often keep this compound in circulation. Experience has shown that consistent respect for its risks, paired with honest conversations about real incidents, keeps people safer than any textbook warning ever could.

Purity Matters for More Than Just Compliance

Manufacturers and labs using methyl 4-chloroacetoacetate don’t ask about purity out of habit. They do it because the stakes are high. In my own time handling small-molecule building blocks, I’ve seen how much project timelines rely on reliable, clean starting materials. Purity isn't a line in a spec sheet—it’s a shield against wasted time and cascading problems in synthesis.

The Typical Numbers You’ll See

Purity for methyl 4-chloroacetoacetate usually lands at 98% or better by GC or HPLC testing. Some suppliers stretch to 99%, but practical commercial batches often stick just below. Even a percent or two makes a difference. Chemical impurities—unreacted starting acids, side-products like methyl acetoacetate, or trace chlorinated solvents—don’t just sit idle in storage. They trigger side reactions, kill yields, and sometimes poison catalysts when you scale up.

I trust a supplier who backs their specs with a real, recent certificate of analysis. Walking into a lab with only a verbal assurance or an old PDF leads straight to batch recalls. Some suppliers go beyond GC/HPLC and show NMR or residue-on-ignition data to address broader impurity concerns, especially for pharmaceutical work. I’ve leaned on these extra assurances when producing API intermediates, where regulatory audit trumps every other concern.

Quality Control Isn’t Only a Laboratory Issue

Working for a contract research organization, my team’s reputation ran on the chemicals we sourced. Inconsistent shipment purity threw us off track. Teams chasing “near spec” batches lost days purifying or troubleshooting reactions instead of focusing on the next step. Every hour spent clarifying or re-purifying methyl 4-chloroacetoacetate took resources away from where they belonged.

Labs sometimes take purity at face value because costs pressure everyone, but my experience says shortcuts don’t pay off. Requesting batch-specific test results or buying from suppliers with transparent track records cuts down on future headaches. I once rushed an order from an unknown vendor to save a week. That week disappeared fast after we spent three days confirming the product wasn't suitable.

Supply, Scalability, and Custom Requests

Bulk users in the agrochemical or pharmaceutical space often push for even tighter specs, like <0.3% of specific impurities or color indices. QC teams might reject an entire lot because of faint yellowing, even when purity reads high. Dealing with these issues means talking directly with suppliers capable of custom syntheses or extra purification steps. It can make sense to start small—test a kilogram, not a ton, to see if the claims match reality.

Sourcing isn’t just a purchasing decision. Every operator wants quick delivery and cost savings, but the purity levels of methyl 4-chloroacetoacetate have a real-world impact most spreadsheet budgets ignore. Auditable, verifiable quality wins out in the end. That’s something I learned by taking tough short-term hits, just to avoid losing bigger in the long run.

Raising the Bar

Trustworthy companies look beyond minimum international standards and match their specifications to end-use demands, documenting every step. As someone who’s faced last-minute specification changes and tough regulatory questions, I value suppliers willing to provide detailed impurity breakdowns, not just a purity percentage. Labs end up with fewer surprises, and research programs get the clear runway they need to produce reliable, impressive results.

| Names | |

| Preferred IUPAC name | Methyl 4-chloro-3-oxobutanoate |

| Other names |

Methyl 4-chloro-3-oxobutanoate

Acetoacetic acid, 4-chloro-, methyl ester 4-Chloroacetoacetic acid methyl ester Methyl 4-chloro-3-oxobutyrate |

| Pronunciation | /ˈmɛθ.ɪl fɔːr ˌklɔːr.oʊ.əˌsiː.təʊ.ˈæs.əˌteɪt/ |

| Preferred IUPAC name | Methyl 4-chloro-3-oxobutanoate |

| Other names |

Methyl 4-chloro-3-oxobutanoate

NSC 89345 Methyl 4-chloroacetoacetate 4-Chloroacetoacetic acid methyl ester Methyl 4-chloro-3-oxobutyrate |

| Pronunciation | /ˈmɛθɪl fɔːr ˌklɔːroʊ əˌsiːtoʊˈæsɪteɪt/ |

| Identifiers | |

| CAS Number | 1516-17-6 |

| 3D model (JSmol) | `3D model (JSmol)` string for **Methyl 4-Chloroacetoacetate** (C5H7ClO3): ``` COC(=O)CC(=O)Cl ``` |

| Beilstein Reference | Beilstein Reference: 1721396 |

| ChEBI | CHEBI:83038 |

| ChEMBL | CHEMBL3118721 |

| ChemSpider | 119450 |

| DrugBank | DB14596 |

| ECHA InfoCard | 100.018.607 |

| Gmelin Reference | 141236 |

| KEGG | C14230 |

| MeSH | D021356 |

| PubChem CID | 87595 |

| RTECS number | AC8225000 |

| UNII | MR9H12F5F2 |

| UN number | UN2735 |

| CompTox Dashboard (EPA) | DTXSID7026173 |

| CAS Number | [40064-34-4] |

| 3D model (JSmol) | `CCCC(=O)C(=O)OC` |

| Beilstein Reference | 1209269 |

| ChEBI | CHEBI:88437 |

| ChEMBL | CHEMBL1229621 |

| ChemSpider | 10234 |

| DrugBank | DB14398 |

| ECHA InfoCard | 17c22cd0-7836-43cd-9e4a-ec1fc91a362e |

| Gmelin Reference | 62310 |

| KEGG | C14137 |

| MeSH | Methyl 4-Chloroacetoacetate" does not have a specific MeSH (Medical Subject Headings) term assigned in the NLM MeSH database. |

| PubChem CID | 107614 |

| RTECS number | AM2975000 |

| UNII | 7WI0Y403JS |

| UN number | UN2650 |

| CompTox Dashboard (EPA) | DJ6RVI2ZXV |

| Properties | |

| Chemical formula | C5H7ClO3 |

| Molar mass | 166.57 g/mol |

| Appearance | Colorless to light yellow liquid |

| Odor | Characteristic |

| Density | 1.345 g/mL at 25 °C(lit.) |

| Solubility in water | Slightly soluble |

| log P | 0.1 |

| Vapor pressure | 0.4 mmHg (20°C) |

| Acidity (pKa) | 7.52 |

| Basicity (pKb) | pKb = 10.7 |

| Magnetic susceptibility (χ) | -51.0·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.442 |

| Viscosity | Viscous liquid |

| Dipole moment | 2.99 D |

| Chemical formula | C5H7ClO3 |

| Molar mass | 164.57 g/mol |

| Appearance | Colorless to light yellow liquid |

| Odor | sweet |

| Density | 1.33 g/cm³ |

| Solubility in water | Slightly soluble |

| log P | 0.1 |

| Vapor pressure | 0.37 mmHg (25 °C) |

| Acidity (pKa) | 7.52 |

| Basicity (pKb) | 8.03 |

| Magnetic susceptibility (χ) | -47.7×10^-6 cm³/mol |

| Refractive index (nD) | 1.435 |

| Viscosity | 1.55 mPa·s (20 °C) |

| Dipole moment | 2.97 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 359.1 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -564.7 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -697.7 kJ/mol |

| Std molar entropy (S⦵298) | 365.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -546.3 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -834.4 kJ/mol |

| Pharmacology | |

| ATC code | |

| ATC code | |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H315, H319, H335 |

| Precautionary statements | P210, P260, P280, P305+P351+P338, P310 |

| NFPA 704 (fire diamond) | 1-2-1-健康蓝-易燃红-反应黄-特殊白 |

| Flash point | Flash point: 110 °C |

| Autoignition temperature | 410 °C |

| Lethal dose or concentration | LD50 oral rat 820 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral, Rat: 940 mg/kg |

| NIOSH | AD3925000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for Methyl 4-Chloroacetoacetate: Not established |

| REL (Recommended) | 10-50°C |

| IDLH (Immediate danger) | N/D |

| Main hazards | Harmful if swallowed. Causes serious eye irritation. Causes skin irritation. May cause respiratory irritation. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS05,GHS07 |

| Signal word | Warning |

| Hazard statements | H302, H315, H319, H335 |

| Precautionary statements | P210, P261, P280, P301+P312, P305+P351+P338, P330, P337+P313 |

| NFPA 704 (fire diamond) | Health: 2, Flammability: 2, Instability: 1, Special: - |

| Flash point | 69 °C |

| Lethal dose or concentration | LD₅₀ (oral, rat): 1,260 mg/kg |

| LD50 (median dose) | LD50 (oral, rat): 940 mg/kg |

| NIOSH | Not listed |

| PEL (Permissible) | Not established |

| REL (Recommended) | 1 mg/m³ |

| IDLH (Immediate danger) | Unknown |

| Related compounds | |

| Related compounds |

Ethyl 4-chloroacetoacetate

Methyl acetoacetate Methyl bromoacetoacetate Methyl 2-chloroacetoacetate Methyl 3-chloroacetoacetate |