Ethyl 4-Chloroacetoacetate: An Industry Commentary

Historical Development

Looking back at the rise of organic synthons, Ethyl 4-Chloroacetoacetate has played a quiet but durable role in modern chemistry. Since the early decades of the 20th century, industry and academic labs have sought versatile and effective intermediates, and this compound checked off the right boxes at just the right time. Its adaptation in pharmaceuticals, agrochemicals, and fine chemical industries didn’t spring up overnight. Progress came through ongoing refinement of acetoacetic ester chemistry, with researchers finding that the 4-chloro derivative could jump into novel reaction pathways. This flexibility created a strong foundation for the expansion of synthetic libraries and offered researchers a tool with both depth and range.

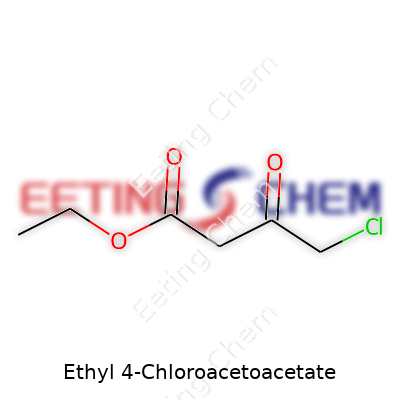

Product Overview

Ethyl 4-Chloroacetoacetate stands out as an organic building block. Chemically, it carries an ethyl ester surrounded by a reactive 4-chloro group and an acetoacetate backbone. This might sound like typical functional group stacking, but the true value only comes once you look at how it serves as a launch pad in molecular transformations. From my years around synthesis benches, I’ve seen how it fast-tracks the creation of heterocycles, streamlines routes to APIs, and adapts to batch or continuous production lines. Suppliers recognize its value, so this material remains a staple in catalogs worldwide.

Physical & Chemical Properties

The substance presents as a clear liquid, faintly yellow, and has a noticeable odor. Its boiling point usually hovers in the range of 110–115°C at reduced pressure, and the density sits around 1.23 g/cm³. The molecule’s structure combines a susceptible α-chloro group and a keto-ester arrangement, which influences its reactivity in both nucleophilic substitution and condensation reactions. The compound demonstrates moderate solubility in organic solvents, like ethanol and dichloromethane, which makes it accessible for various process set-ups. Watching this reagent interact under typical lab conditions, one can appreciate its readiness to react, balanced by enough stability for straightforward handling.

Technical Specifications & Labeling

Manufacturers frequently guarantee purity in the range of 98% or greater, with impurity profiles including low levels of unreacted esters and halogenated by-products. Labels spell out key identifiers: batch number, production date, CAS number (5979-10-4), and hazard statements covering irritancy to skin and eyes. Standard packaging uses amber glass bottles or HDPE containers, marked with GHS pictograms to stress the importance of protective handling. Tech sheets outline crucial metrics: refractive index, spectral data, assay by GC or NMR, and water content by Karl Fischer titration. This level of detail helps laboratories put safety and quality first, with no shortcuts.

Preparation Method

The main synthetic route usually hinges on a chloroacetylation of ethyl acetoacetate. One reliable approach involves the action of phosphorus oxychloride on ethyl acetoacetate with basic catalysts, which guards the carbonyl group and allows controlled insertion of the chloro substituent. Keeping careful temperature control during addition of chlorinating agents proves vital. Over-chlorination or byproduct generation can disrupt yields and complicate downstream separation, so reaction parameters require real attention. After the reaction, standard liquid extraction and vacuum distillation work well to clean up the product. This entire process reminds any chemist that a reaction’s reputation depends on both yield and purity.

Chemical Reactions & Modifications

Ethyl 4-Chloroacetoacetate serves as a springboard for a range of transformations. Its electrophilic α-chloro group allows for nucleophilic displacement, making it possible to drop in amines, thiols, or even azides to build up a broad family of β-keto compounds. The dicarbonyl system opens up aldol-type condensations, Michael additions, and cyclizations leading to pyrazoles, pyrimidines, or isoxazoles. Over the years, this compound cropped up in protocols for synthesizing active pharmaceutical ingredients or advanced intermediates. Its ability to participate in multi-step reaction sequences, including transition-metal-catalyzed couplings, still attracts fresh research today. My own work with these transformations has proven that reliable functional group behavior saves time and headaches, both in bench-scale studies and production processes.

Synonyms & Product Names

Chemists and suppliers use several names for this compound, depending on the application or region. Some standard synonyms include Ethyl 4-chlor-3-oxobutanoate, Ethyl 4-chloro-3-oxobutanoate, and simply 4-Chloroacetoacetic acid ethyl ester. In some supplier catalogs, “ECAA” pops up as shorthand, reflecting decades of shorthand in technical correspondence. Whatever the name chosen, the distinct combination of the ethyl group, the chloro atom at the γ-position, and the acetoacetate skeleton speaks to a unified identity. Reliable sourcing depends on this shared language, so anyone making orders or designing experiments checks all the labels before hitting “submit.”

Safety & Operational Standards

The presence of a chloro group and a reactive electrophilic center calls for smart handling strategies to protect both lab workers and equipment. Exposure can irritate the skin, eyes, and respiratory tract if inhaled, so use of gloves, splash-resistant goggles, and fume hoods falls under basic protocol. Spills require containment with absorbent pads, followed by washing surfaces with dilute base—chlorinated residues have no place in the waste stream. Storage in tightly sealed containers, cool and dark, reduces risk of breakdown or volatilization. Industry standards draw on OSHA, EU REACH, and GHS guidelines for labeling and safe transport. Regular training and up-to-date safety data sheets make the real difference when a delay or handling error puts the workday at risk.

Application Area

This compound appears across pharmaceutical and fine chemical syntheses, especially where assembly of functionalized heterocycles and active molecules is required. Agrochemical development uses this ester in the construction of herbicides and fungicides that depend on chloro-substituted scaffolds. Dye manufacturers and pigment researchers sometimes turn to it for novel chromophores. From experience, the most interesting methods exploit its dual reactivity, linking two reaction sequences in one step. Demand often spikes in research settings working on compound libraries, SAR studies, or process optimization for patent-protected drugs.

Research & Development

The current wave of interest in green and sustainable chemistry has nudged researchers to reevaluate the synthetic methods surrounding 4-chloroacetoacetate chemistry. Academic papers cover catalyst development, solvent minimization, and flow-based methods to push yields up and cut waste streams. Research teams in pharma and agrochemical firms continue to track new modifications, trying to expand the reach of this intermediate into NCEs and bioactive agents. A well-crafted publication with detailed reproducibility sparks further investigation, and so the conversation grows. Some labs have looked at automated synthesis, using digital feedback to fine-tune reaction pathways. All this shows steady innovation rather than yesterday’s routine.

Toxicity Research

Toxicological evaluation forms a critical background to the use of Ethyl 4-Chloroacetoacetate. Much of the available data comes from acute exposure studies, which show moderate risks of irritation and sensitization. Researchers have looked at both skin contact risks and inhalation hazards, with rodent studies tracking both lethality and symptoms from sub-lethal doses. Environmental fate data remain more limited, but possible aquatic toxicity to fish and invertebrates highlights the importance of strict disposal strategies. My time working with similar reagents taught me never to assume safety based on analogs—each new chlorinated compound deserves careful review. Industry lags when it shrugs off such insights, so continuous support for deeper testing and transparent reporting stays essential.

Future Prospects

The future for Ethyl 4-Chloroacetoacetate ties into growing demand for new pharmaceuticals, advanced polymers, and refined agrochemical agents. As more R&D teams push toward cleaner syntheses, one can expect process improvements with less waste, lower energy use, and safer reaction conditions. Novel catalysts and biocatalytic pathways may allow selective modification of more complex precursors, cutting out steps and reducing reliance on harsh chlorinating agents. Regulatory changes around chlorinated wastes could drive more recycling or closed-loop production, making suppliers step up their game. These advances are not abstract trends but forces shaping the next generation of synthesis, with this old workhorse finding a continuing place in diverse projects—proof that innovation and tradition can run side by side in chemical development.

Unlocking the Formula

I’ve often seen chemistry textbooks almost skim past the details when it comes to naming and understanding chemical compounds. Ethyl 4-chloroacetoacetate sounds complex, but it breaks down pretty simply. Digging into its formula, it’s C6H9ClO3. Each letter and number reflects the structure, which impacts everything from its role in pharmaceutical labs to the regulations folks have to follow whenever this chemical shows up in manufacturing.

Why Ethyl 4-Chloroacetoacetate Pops Up in Industry

Chemists rely on ethyl 4-chloroacetoacetate for making other compounds, especially pharmaceuticals and agrochemicals. I’ve read patents and scientific journals: this molecule keeps popping up. It’s often used because that chlorine atom (the Cl) allows the rest of the molecule to react in unique and useful ways, speeding up synthesis steps or providing building blocks for more advanced molecules. Its structure, C6H9ClO3, gives it properties that labs need when trying to create specific intermediates for drugs or crop protection products.

Safety Isn’t Just a Buzzword

I’ve worked in labs where the importance of safety can't be overstated. Ethyl 4-chloroacetoacetate’s formula means it comes with the characteristic risks of chlorinated organic chemicals. That chlorine atom isn’t just there for show—it drives reactivity, sometimes making spills and exposure more hazardous. Reliable safety data sheets warn about skin, eye, and respiratory irritation, as well as possible environmental effects if mishandled. Investing time in proper storage practices and personal protective equipment pays off, both in health and in workflow. Being careless around chemicals with reactive groups hasn’t made a single process more efficient, ever.

Science with an Eye Toward Responsibility

Responsibility doesn’t start and end inside the lab. C6H9ClO3’s reactivity, especially because of that chloro group, means scientists and manufacturers carry an ethical responsibility. From personal experience, it helps to keep documentation airtight—not just for safety, but for traceability. Regulators keep a close watch on the handling and shipping of compounds like this, asking for clear chain-of-custody and usage protocols. Manufacturing teams have adapted, tracing chemicals through their entire life cycle, from delivery to disposal.

Looking Toward Solutions

Not every challenge needs a new invention. Sometimes it’s about refining workflows. In the context of ethyl 4-chloroacetoacetate, spending the extra time on up-to-date training for everyone in the lab saves headaches down the road. Replacing older storage equipment with ventilated, explosion-proof cabinets gives peace of mind. And open communication between chemists, safety officers, and procurement staff helps spot potential issues before they escalate. Sharing lessons among teams—what worked, what didn’t—pushes everyone closer to best practices.

Why Understanding the Formula Matters

It’s easy to treat chemical formulas as simple combinations of letters and numbers. These symbols reveal a lot about how a substance interacts with people, equipment, and the environment. C6H9ClO3 isn’t just a code for textbooks—it signals real-world implications for safety, compliance, and innovation. And as the chemistry world keeps advancing, ensuring every team member grasp not just what a chemical is, but how it behaves, only becomes more important.

Key Ingredient in Pharmaceutical Synthesis

Ethyl 4-chloroacetoacetate plays a steady role in pharmaceutical manufacturing. It pops up during the crafting of many complex molecules, including some used in heart medications, pain relief, and antibiotics. For chemists plotting the precise steps that link small building blocks into useful treatments, this reagent opens useful shortcuts. The chlorine atom on its backbone is reactive, making it a handy starting point for creating new bonds. I remember helping out in a university lab where our team tried to make anti-tumor compounds; Ethyl 4-chloroacetoacetate showed up a few times because it made a tricky step surprisingly manageable. According to research published in the Journal of Medicinal Chemistry, this compound’s structure helps attach new features onto rings and chains — a necessity for fine-tuning how a drug interacts with its target.

Crop Protection and Agrochemical Sector

Farmers don’t often hear about the fine details in the pesticides and herbicides they trust each season, but chemists working in crop science use Ethyl 4-chloroacetoacetate behind the scenes. Several common fungicides are built starting with this molecule. The structure lets research teams introduce new features, making compounds that fight fungi or insects more effectively without breaking the bank or causing unnecessary harm to helpful insects. Regulatory agencies like the EU’s European Food Safety Authority have tracked its safe use as part of broader compounds found in many modern pesticide products.

Flavor and Fragrance Manufacturing

Anyone who’s ever opened a bottle of synthetic lemon or vanilla in a commercial kitchen has caught a whiff of work done with help from core building blocks like this one. Flavor makers rely on the compound for making more complex aroma molecules. It allows for addition of side groups that lead to the tangy or floral notes bakers and perfumers demand. The chemistry can turn otherwise bland mixtures into signature scents that help products stand out on crowded supermarket shelves. Industry sources, including the Flavor and Extract Manufacturers Association, note how ingredients like Ethyl 4-chloroacetoacetate streamline the steps needed to achieve high purity and consistency, especially as formulas adapt to new tastes or regulatory changes.

Specialty Dyes and Pigments

Color runs deep in industries from textiles to highlighters. Ethyl 4-chloroacetoacetate lends itself to dye synthesis because its backbone helps lock color molecules onto fabrics or surfaces for lasting vibrancy. I‘ve met folks in the textile business facing colorfastness issues, and chemists pointed to this reagent as one that lets them update dye molecules for better wash resistance. Innovations in this space help reduce waste, as more color stays put after the rinse, which both factories and the environment appreciate.

Looking at Safer Handling and Sustainable Alternatives

This compound’s helpful features don’t let users skip safety. It has a certain pungency and can pose hazards if handled carelessly. Workplace safety guidelines insist on good ventilation, gloves, and goggles. As more companies focus on green chemistry, some researchers look for less persistent compounds with similar flexibility. The American Chemical Society and other organizations promote sharing proven green alternatives, but for now, Ethyl 4-chloroacetoacetate remains a steady choice in the toolkit for many essential goods.

Keeping People and Places Safe Around Ethyl 4-Chloroacetoacetate

Chemicals like Ethyl 4-Chloroacetoacetate do not forgive mistakes. Fresh out of the bottle, this liquid carries a sharp smell and won’t just burn your skin or eyes—it can sneak up through the air, get into your lungs, or even hurt equipment if you’re careless. Labs and factories—any place using this compound—should treat it with respect. Sometimes I think back to a morning with stinging hands in grad school because I skipped gloves once with a much tamer ester. Never again. Here’s how you keep similar messes out of your work and life.

Practical Storage Steps Everyone Should Follow

Never leave Ethyl 4-Chloroacetoacetate in a spot that gets direct sunshine or warmth. Leave the container anywhere near a heating vent, and you risk vapors building pressure or the chemical breaking down faster. Dark bottles, tight caps, and a room below room temperature—those make up the minimum. Walk into a chemical storage room worth its name and you’ll spot labels, clear shelves, and tight controls over who comes in.

Keep moisture away at all costs. Any leak in the cap, any bit of water vapor in the air, and this stuff reacts—sometimes making something far nastier. In practice, smart labs toss a packet of desiccant into storage cabinets. Nobody trusts “good enough” here. Don’t let food or drinks anywhere near your chemical store either. Accidents grow out of small overlaps.

Why a Little Personal Protection Never Hurts

Old-timers like to joke about “washing chemicals off in the sink,” but that gets people hurt. Gloves and goggles bring peace of mind. Splash one drop in your eye, and you’ll never work without glasses again. Use nitrile or neoprene gloves; latex ones melt or fail too fast around esters. Wear long sleeves. Have a fume hood running. The less you breathe, the better you feel after hours in the lab.

Handling Spills and Waste

Even in places where folks know what they’re doing, spills pop up. Granular spill kits—clay or specific absorbers—make cleanups quick. Skip the paper towels; those let vapors through, or worse, they catch fire. Waste bins must shut tight, stand away from heat, and carry clear markings. Most places call a contractor to handle chemical disposal, or they partner with a hazardous waste team. You dump this compound down a regular drain, and you risk sickening the people who keep water safe in your town.

Staying Ahead of Incidents

Regular training works better than warning posters taped to a wall. Have an emergency shower and eyewash close to work areas. Check labels each time you pull down a bottle—worn-out stickers and fading ink hide mistakes. If someone gets a splash, rinse with cold running water, then call poison control. Don’t play around or hope for the best.

Proper care with Ethyl 4-Chloroacetoacetate means nobody gets hurt, goods don’t get lost, and labs keep running without drama. Respect the risks, use the right gear, and set routines anyone can check—these basics keep workdays smooth and safe.

Why CAS Numbers Matter in Chemistry and Industry

My first hands-on introduction to chemical identifiers came in a university lab, staring at three nearly identical white bottles that could have created dramatically different reactions in the flask. The difference? The CAS numbers stamped on the labels. Ethyl 4-chloroacetoacetate carries its own unique number in this system: 609-15-4.

Researchers and people working in chemical supply lean on CAS numbers. They aren’t just there to look official. With supply chains running global, a chemical name sometimes gets translated into dozens of variants. Someone calls it “ethyl 4-chloro-3-oxobutanoate,” someone else writes “ethyl 2-chloroacetoacetate.” Labels in a warehouse or customs declaration don’t always match what someone learned during training. The CAS number cuts through confusion.

Making Science Safer and Traceable

In my job, a lab manager once spent a good chunk of time tracing the provenance of a mislabeled container, trying to match up the paperwork with stock on the shelf. For regulated chemicals, the CAS number tells authorities and shipping firms exactly what’s in a drum or a vial. Ethyl 4-chloroacetoacetate’s CAS number, 609-15-4, links directly to global safety sheets, exposure guidelines, and protocols for emergencies. No code, and you’re left guessing.

Mistakes in labeling don’t just mean lost time or embarassed emails. They can cause harm. Toxicology studies, environmental guidelines, and safe handling instructions don’t match up if you aren’t sure what substance you’re dealing with. With thousands of similar-sounding compounds circulating, a unique CAS number offers a layer of protection against accidental substitutions.

The CAS Number’s Role in Research and Discovery

Anyone who’s mapped out a synthetic pathway knows that intermediates like ethyl 4-chloroacetoacetate form the stepping stones between imagination and a finished product. Say the goal involves building a new active ingredient for agriculture or pharmaceuticals. Scientists rely on reliable sourcing. Reproducibility in research means being able to specify reagents precisely — not just their names, but their exact identities. That’s what CAS 609-15-4 delivers.

Patent examiners, journal editors, and regulatory inspectors expect reports to include these codes. This isn’t bureaucracy for bureaucracy’s sake. Research funding, publication, and commercial licensing depend on playing by these rules. I’ve seen manuscripts rejected and projects stalled because a reagent couldn’t be unambiguously tracked to its source. The CAS system removes uncertainty.

Clarity Supports Progress and Innovation

Better organization and safety keep labs running smoother, but tracking chemicals by unique numbers plays a bigger part in tackling real-world challenges. Environmental agencies monitoring for residues use CAS numbers in their databases. Doctors and toxicologists depend on the same identifier to guide treatment after accidental exposure. Without the standardized approach, valuable knowledge and progress are lost in translation.

Some mistakes carry lifelong consequences. A solid paper trail—anchored by a code like 609-15-4 for ethyl 4-chloroacetoacetate—limits risks. Teams collaborating on different continents refer to the same substance. Industry, regulators, and everyday people benefit from this careful attention to detail. A small number on a label makes sure discoveries, safety, and trust aren’t left to chance.

Getting to Know Its Appearance

Ethyl 4-chloroacetoacetate stands out as a chemical that you won’t mistake for something else on the lab bench. Pour it into a beaker, and you spot a colorless to slightly yellow liquid. The faint yellow hue grows more noticeable with age, exposure to air, or if the sample carries traces of impurities. When I worked with this compound in an undergraduate lab, the bottle had a faint but distinct chemical smell—sharp, not overpowering, a reminder to keep the cap on and work under a vent.

It moves easily, like most small esters, with a low viscosity. No crystals, no powders, nothing sludgy. If you chill it below room temperature, especially near zero Celsius, you might find the liquid thickening but it rarely turns fully solid except at much colder conditions—below about -50°C.

Physical Properties that Matter in the Lab

This chemical boils at about 210°C. Leave it on a hot plate too long, and you catch the typical ester odor as vapor drifts up. It doesn’t just vaporize and disappear; it lingers, which hints at some persistence in the air and a need for proper ventilation.

It’s not one to dissolve in water; try mixing some in a basic chemistry classroom, and you’ll notice it floats in droplets. You need alcohols, acetone, or chloroform to get it fully into solution. That matters in both research and in industry, because any cleanup, reaction planning, or waste management should factor in those solvent choices.

Gravity does its job straightforwardly here. A density around 1.22 grams per milliliter means ethyl 4-chloroacetoacetate is heavier than water. Tip a test tube and it settles to the bottom, not mixing unless you agitate or use a solvent.

Facts and Safety Issues Worth Knowing

People mostly encounter ethyl 4-chloroacetoacetate in pharmaceuticals and dye synthesis. Its physical form—runny liquid, mildly smelly—hints at volatility and possible risk. A spill fills a small room with an acrid aroma, not just a cosmetic issue; those vapors irritate eyes and noses. Gloves, goggles, and working under a hood aren’t optional luxuries, they keep you working safely.

Accidents with this chemical made headlines at least twice during my graduate studies, both tied to careless pipetting and ignoring fume hoods. Lab manuals hammer home those safety steps for a reason. The compound itself reacts and breaks down pretty quickly with bases, releasing fumes no one wants to breathe. So cleaning and disposal end up just as important as careful measurement.

Making Sense of Its Role

This liquid asks researchers for respect; it offers value, but only to those who take basic precautions. Industry and academic users alike rely on clear labeling, dated bottles, safe transfer protocols, and good ventilation to avoid trouble.

It pays to check your containers for discoloration or a strong odor before each use. Facilities should keep eye wash stations ready and train staff properly—this isn’t just regulatory red tape, it cuts down on injury and panic. Spill kits make a difference, and so does minimizing storage time. With an organized workspace and a watchful eye on storage conditions—low humidity, away from sunlight—problems from aging or unintended reactions drop off sharply.

| Names | |

| Preferred IUPAC name | Ethyl 4-chloro-3-oxobutanoate |

| Other names |

Ethyl 4-chloro-3-oxobutanoate

Ethyl chloroacetoacetate 4-Chloroacetoacetic acid ethyl ester Ethyl 4-chloroacetoacetate |

| Pronunciation | /ˈiːθɪl fɔːr ˌklɔːroʊ əˌsiːtoʊˈæseteɪt/ |

| Preferred IUPAC name | Ethyl 4-chloro-3-oxobutanoate |

| Other names |

Ethyl 4-chloro-3-oxobutanoate

Ethyl chloroacetoacetate 4-Chloroacetoacetic acid ethyl ester |

| Pronunciation | /ˈiːθɪl fɔːr ˌklɔːroʊ əˌsiːtoʊˈæsɪteɪt/ |

| Identifiers | |

| CAS Number | 609-15-4 |

| 3D model (JSmol) | `3D model (JSmol)` string for **Ethyl 4-Chloroacetoacetate**: ``` CCOC(=O)CC(=O)Cl ``` |

| Beilstein Reference | 344789 |

| ChEBI | CHEBI:36743 |

| ChEMBL | CHEMBL47986 |

| ChemSpider | 67817 |

| DrugBank | DB14298 |

| ECHA InfoCard | 100.010.764 |

| EC Number | 211-891-9 |

| Gmelin Reference | 164683 |

| KEGG | C14320 |

| MeSH | D017964 |

| PubChem CID | 86997 |

| RTECS number | AF8225000 |

| UNII | 4A6I079324 |

| UN number | UN2670 |

| CAS Number | 638-07-3 |

| Beilstein Reference | 1209223 |

| ChEBI | CHEBI:41441 |

| ChEMBL | CHEMBL414267 |

| ChemSpider | 53268 |

| DrugBank | DB13880 |

| ECHA InfoCard | 03a8c250-122e-4e80-8179-2c5f9c83ab6e |

| EC Number | 212-471-4 |

| Gmelin Reference | 157788 |

| KEGG | C14318 |

| MeSH | D002492 |

| PubChem CID | 87121 |

| RTECS number | AF8750000 |

| UNII | 268730VJ3G |

| UN number | UN2679 |

| Properties | |

| Chemical formula | C6H9ClO3 |

| Molar mass | 178.62 g/mol |

| Appearance | Colorless to pale yellow liquid |

| Odor | Fruity |

| Density | 1.26 g/mL at 25 °C |

| Solubility in water | Slightly soluble |

| log P | 0.9 |

| Vapor pressure | 0.3 mmHg (25°C) |

| Acidity (pKa) | 10.7 |

| Basicity (pKb) | 12.96 |

| Magnetic susceptibility (χ) | -48.2 × 10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.439 |

| Viscosity | 1.665 mPa.s at 20 °C |

| Dipole moment | 2.94 D |

| Chemical formula | C6H9ClO3 |

| Molar mass | 178.62 g/mol |

| Appearance | Colorless to light yellow liquid |

| Odor | fruity |

| Density | 1.253 g/mL at 25 °C(lit.) |

| Solubility in water | Insoluble in water |

| log P | 0.9 |

| Vapor pressure | 0.33 mmHg (25 °C) |

| Acidity (pKa) | 7.45 |

| Basicity (pKb) | pKb ≈ 13.2 |

| Magnetic susceptibility (χ) | -50.3 × 10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.439 |

| Viscosity | 1.227 mPa·s (20 °C) |

| Dipole moment | 2.97 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 388.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -526.7 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | No data |

| Std molar entropy (S⦵298) | 363.6 J·mol⁻¹·K⁻¹ |

| Hazards | |

| Main hazards | Harmful if swallowed. Causes skin irritation. Causes serious eye irritation. May cause respiratory irritation. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | H226, H302, H315, H319 |

| Precautionary statements | P261, P264, P271, P272, P273, P280, P302+P352, P305+P351+P338, P310, P321, P332+P313, P362+P364, P501 |

| Flash point | 86 °C |

| Lethal dose or concentration | LD₅₀ (oral, rat): 1,620 mg/kg |

| LD50 (median dose) | LD50 (oral, rat): 780 mg/kg |

| NIOSH | AM6990000 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 0.1 ppm |

| Main hazards | Harmful if swallowed, causes skin irritation, causes serious eye irritation. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | H302, H315, H319, H335 |

| Precautionary statements | P210, P261, P280, P305+P351+P338, P304+P340, P312 |

| NFPA 704 (fire diamond) | 1-2-1-0 |

| Flash point | 76 °C (closed cup) |

| Lethal dose or concentration | LD₅₀ (oral, rat): 1910 mg/kg |

| LD50 (median dose) | LD50 (oral, rat): 1,225 mg/kg |

| NIOSH | AS5885000 |

| PEL (Permissible) | Not established |

| IDLH (Immediate danger) | Unknown |

| Related compounds | |

| Related compounds |

Methyl 4-chloroacetoacetate

Ethyl acetoacetate Ethyl 2-chloroacetoacetate Ethyl 2-bromoacetoacetate Ethyl 4-bromoacetoacetate |

| Related compounds |

Methyl 4-Chloroacetoacetate

Ethyl Acetoacetate Ethyl 2-Chloroacetoacetate Ethyl 4-Bromoacetoacetate Ethyl 4-Fluoroacetoacetate Ethyl 4-Iodoacetoacetate Ethyl 4-Chlorocrotonate |