Benzonitrile: Shaping Chemistry Through the Years

Historical Development

Benzonitrile stands as one of those backbone molecules that quietly threads through the story of organic chemistry’s evolution. First isolated by Hermann Fehling back in 1844, this aromatic nitrile marked a milestone in the ongoing quest for new building blocks. Fehling distilled benzonitrile from ammonium benzoate, unknowingly setting off a wave of innovation among chemists searching for new methods to produce and utilize nitriles. Its presence in the organic chemistry curriculum is no accident; benzonitrile sits midway between basic benzenes and more complex aromatic compounds, acting as a springboard for both industrial advances and academic curiosity. Over the decades, its reliable reactivity and manageable toxicity have made it a go-to for everything from synthetic explorations to scalable industry applications. The molecule’s history reflects chemistry’s broader push for functional, versatile compounds that open doors to countless derivations.

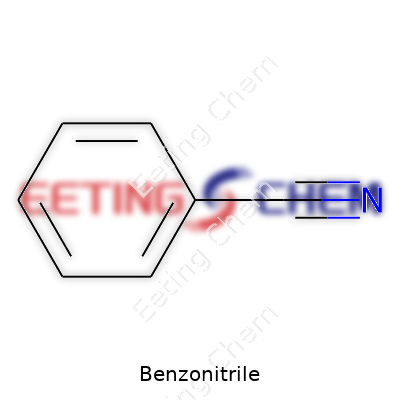

Product Overview

Benzonitrile is more than just another clear, colorless liquid. Chemists and manufacturers recognize it for its strong, distinctive almond-like odor and utility across different domains, including pharmaceuticals, solvent production, and polymer design. Its structure—a benzene ring bonded to a nitrile group—enables both straightforward use as a solvent and creative application as a synthesis intermediate. Compared to other solvents, it presents a higher polarity without being too aggressive, which makes handling less problematic than with some more volatile nitriles or aromatics. Industry uptake has accelerated in the last two decades, especially with the global rise in specialty chemicals.

Physical & Chemical Properties

Benzonitrile carries the formula C7H5N and a molecular weight of about 103.12 g/mol. At room temperature, it appears as a colorless to pale yellow liquid. With a boiling point around 191°C and a melting point near -13°C, it shows moderate volatility during lab or plant-scale handling. Its density, close to 1.01 g/cm³, means it mixes well with various organic solvents, though it separates from water. The presence of the nitrile group extends its chemical flexibility—acting as both an electron-withdrawing group and a reactive handle for further modification.

Technical Specifications & Labeling

On a production scale, benzonitrile usually arrives at a minimum purity of 99%, with water content tightly controlled to below 0.2%, reflecting its common use in moisture-sensitive reactions. Packaging often includes amber glass or steel drums, with labeling that highlights its flammability, acute toxicity, and environmental hazards, as regulation demands across North America, Europe, and Asia. Safety Data Sheets lay out exact measures for storage, spill control, and personal protection, reinforcing each link in the supply chain.

Preparation Method

Large-scale benzonitrile is produced most commonly by the dehydration of benzamide or by the ammoxidation of toluene. Traditional laboratory synthesis still sticks with older, reliable routes; the classic dehydration uses agents like phosphorus pentachloride or thionyl chloride, converting benzamide in carefully controlled conditions. In the industrial sphere, the ammoxidation of toluene—blending ammonia with oxygen and a catalyst—provides higher yields, lower costs, and less waste, echoing the industry’s move toward more sustainable practices. This scaling up from a once-rare compound to a widely traded chemical took both persistence and creative engineering.

Chemical Reactions & Modifications

The appeal of benzonitrile comes from its nimble reactivity. Chemists routinely reduce it to benzylamine through hydrogenation, a staple transformation in pharmaceutical and agricultural research. The nitrile group also operates as a gateway for hydrolysis, forming benzoic acid under acidic or basic conditions. More intricate methods see it as a backbone for complex aromatic ring substitutions, for example, the introduction of functional groups via metal-catalyzed couplings. This versatility ensures it remains foundational in both research and commercial compound development.

Synonyms & Product Names

Benzonitrile goes by plenty of aliases, not just to satisfy regulatory requirements, but as a result of its long history. It turns up under the names cyanobenzene, phenyl cyanide, and benzylnitrile. On commercial shipments, one might find IUPAC identifiers or trade names, each reflecting local standards but always pointing back to the core molecule’s distinctive structure.

Safety & Operational Standards

Handling benzonitrile involves a firm respect for its chemical risks. The compound ranks as moderately toxic by inhalation, ingestion, or skin contact; it delivers a good reminder that even well-understood, familiar chemicals call for strict procedures and protective measures. Labs and factories both control exposure by using fume hoods, gloves, and proper eye protection. Ventilated workspaces and careful waste disposal also accompany its use. Spills call for absorbents and swift cleanup, as even small quantities can pose health issues and environmental risks. Regulatory frameworks such as OSHA, REACH, and the Globally Harmonized System spell out these requirements in detail.

Application Area

Applications for benzonitrile stretch from day-to-day lab solvent jobs to specialized roles in creating high-value pharmaceuticals, agrochemicals, and advanced polymers. It pops up as a reaction medium in cross-coupling chemistry, letting researchers fine-tune selectivity and yield. In pharma, benzonitrile shows up as a starting material toward antihistamines, anti-inflammatory drugs, and newer generations of kinase inhibitors. Technologists prize it in liquid crystal display manufacturing and in the synthesis of novel monomers for specialty plastics. Scientists keep finding new roles thanks to its stable yet reactive personality, always bridging gaps between basic research and large-scale manufacturing.

Research & Development

Discovery thrives on versatile molecules, and benzonitrile doesn't disappoint. Researchers harness its unique electronic characteristics to design new catalytic systems, improve green chemistry protocols, and model pollutant breakdown in environmental studies. Computational chemists use it as a model substrate, probing electron transfer, aromaticity, and photochemistry. This compound’s simple structure and distinct reactivity make it ideal for teaching fundamental concepts in organic chemistry, as well as for developing new synthetic tools that will feed into cleaner, safer chemical production for tomorrow.

Toxicity Research

Toxicological studies flag benzonitrile for its metabolic conversion to cyanide—an acute hazard in both accidental and occupational exposures. Animal data and reported human incidents document its ability to cause respiratory distress, neurological impairment, and, in severe cases, fatal outcomes at high ingestion or inhalation doses. Regulatory exposure limits reflect these risks, prompting modern manufacturing to automate and minimize direct contact. Research continues on detoxification strategies, both at the enzyme-inhibitor level and through engineering safer process enclosures for workers. These ongoing efforts underpin both workplace safety and environmental risk assessments, especially in regions with a long industrial heritage.

Future Prospects

Benzonitrile’s straightforward profile belies ongoing potential for innovation. Synthetic chemists remain keen on harnessing mild, selective transformations—especially catalytic hydrogenations and green oxidation pathways—to add value or sustainability to the supply chain. Its role as a model solvent and intermediate keeps expanding as new reaction types are developed. Toxicologists and occupational hygienists keep exploring safer encapsulation, detection, and remediation approaches. As pressure mounts for cleaner chemistries and tighter safety regimes, benzonitrile sits at the intersection of tradition and reinvention, its utility shaped by equal parts necessity and possibility.

What’s Hiding Behind the Name

Benzonitrile—some folks tune out after hearing a name like that. But this chemical crops up in more places than most people think. Coming out of the lab as a clear liquid, it smells a bit like almonds, a little like bitter cherry. Most of us would never notice a bottle of it, but chemists see a toolkit in every drop.

Running the Show in Pharmaceuticals

Some of the medicines in your cabinet come about thanks to chemicals like benzonitrile. Take the search for new treatments: drug companies need raw building blocks to piece together complicated molecules. Benzonitrile acts like a bridge—a point between simple ingredients and a finished drug. Chemists use it as a “precursor.” It gives them a shortcut to make all sorts of things, from antihistamines to antifungals. This saves time, money, and keeps labs safer by making the chemistry more predictable.

Most synthetic medicines don’t come straight from nature; they’re pieced together step by step. The carbon-nitrogen bond in benzonitrile carries a lot of possibilities. When scientists break it apart or change it, they can steer the reaction toward whole new families of drugs. This backbone allows wide exploration during drug discovery, especially when speed is so important and time in the lab costs money.

The Lesser-Known Uses: Dyes, Pesticides and Electronics

Step into the textile world, and benzonitrile helps crank out dyes that color everything from blue jeans to t-shirts. Chemical companies tweak the structure of benzonitrile to make pigments stick well, fade less, and stay bright after weeks of sunlight and washing. I used to visit a dye house as a student, and the huge vats always reeked of these odd-smelling starting materials. A little goes a long way, but that’s what keeps yellow new and shirts looking crisp.

Pesticide makers lean on benzonitrile chemistry, too. Farmers need solutions that knock out pests without making food toxic. Certain insecticides and herbicides start with this reliable molecule, letting companies fine-tune effectiveness or stick to stricter safety rules. Science guides these upgrades—less drift into waterways, less impact on pollinators, better harvests without harsh trade-offs.

In another corner, benzonitrile plays a quiet role in liquid crystal displays. Everyone checks a phone screen countless times a day, and chemicals like benzonitrile help the liquid crystals line up just right, making sure the screen changes quickly and colors pop. I remember reading that, in the 1970s, researchers spent years chasing the perfect compounds for display panels. Benzonitrile and its cousins still get used for their electric properties in these panels and other electronics.

The Safety Piece And Environmental Watch

Like many industrial chemicals, benzonitrile calls for respect in the lab. Inhalation or skin contact shouldn’t be taken lightly; it can irritate or harm the body in enough quantity. Chemical plants and research labs set up safeguards—ventilation, gloves, smart storage practices—because a spill or accident chills productivity and puts real people at risk.

On the environmental side, benzonitrile isn’t a notorious polluter, but it doesn’t break down easily in nature. That means careful disposal counts. Efforts focus on efficient, “greener” synthesis to lower waste and reduce the need for hazardous solvents. Many companies chase alternative pathways that keep the chemistry useful but shrink its environmental footprint. Investing in safer production pays off in community trust and keeps water supplies cleaner over time.

Making Chemistry Work For People

Everyday convenience—bright clothes, vivid screens, easy dosing at the pharmacy—often owes something to the quiet backbone supplied by simple chemicals like benzonitrile. Real progress shows up not just in what we can make, but in how responsibly we use these tools. Support for stronger research, smart safety practices, and waste reduction keeps these building blocks at work without bringing new headaches. Good chemistry isn’t just about clever reactions—it’s about connecting the lab bench to better lives outside.

Understanding the Issues with Benzonitrile

Benzonitrile doesn’t grab headlines like some other chemicals, but it’s no stranger in labs or certain manufacturing jobs. Most people won't find it cleaning out drawers at home, but anyone working in chemical plants, science classrooms, or certain factories might cross paths with it. Some plastics, pharmaceuticals, and dyes use benzonitrile during production. That means, for a good part of the workforce, understanding its health risks isn’t just academic—it’s about staying safe on the job.

Direct Effects on Health

Chemical exposure in the workplace isn't some distant topic. I’ve watched coworkers handle myriad substances with gloves one minute and a boxed sandwich the next. Mistakes happen, and without clear information, real harm follows. Benzonitrile can irritate skin and eyes on contact. Breathing in vapor sometimes leads to sore throat, coughing, or trouble breathing. Extended exposure makes things worse. I remember guidelines from safety training warning about headaches, nausea, or in rare cases, more serious effects like seizures and trouble walking if a large amount enters the body.

The science here backs up personal experience. The U.S. National Institute for Occupational Safety and Health (NIOSH) and other authorities lay out clear cautions: Exposure limits are set because benzonitrile can disrupt the body’s ability to transport oxygen if enough gets in. That’s not just a theoretical risk—one wrong move in a busy workplace and trouble arrives fast.

Exposure Doesn’t Happen in a Bubble

Some producers take safety seriously, putting in place air monitoring and double layers of personal protective equipment (PPE). Other job sites, especially in older buildings or understaffed labs, cut corners. Rushed safety talks and missing gloves create the very situations where chemicals like benzonitrile go from background nuisance to urgent problem. Occupational exposure often depends on workplace culture, and everyone from managers to part-timers plays a role in safety.

Plenty of workers still don’t get enough information. It's not rare to hear new hires say, “Nobody told me what that smell was,” or “I just washed my hands after, figured that was enough.” Knowledge gaps turn routine exposures into genuine harm. Looking out for each other means more than posting a sign by the sink. The right training and regular reminders go further than any poster.

What the Research Shows

Groups like the Environmental Protection Agency (EPA) and Centers for Disease Control and Prevention (CDC) agree: Benzonitrile causes trouble if handled poorly. Long-term animal studies, though limited, hint at possible liver and nerve damage with high, repeated exposures. So far, evidence doesn’t link it to cancer in people, but laboratories don’t always replicate messier, real-world workplaces. Applying the “better safe than sorry” rule feels appropriate, especially in jobs that involve daily chemical handling.

Reducing Risk—And Why It Matters

Plenty of workplaces handle benzonitrile without anyone getting sick. What sets them apart isn’t just luck. Good ventilation, routine equipment checks, accessible PPE, and a culture that lets people raise concerns without fear of blowback make a huge difference. Investing in these basics saves health, improves morale, and cuts costs due to fewer lost workdays or fines for safety lapses. Worker health isn’t a box to check—it’s the foundation of any reliable operation.

Doctors, regulators, and workers all agree: A little care with chemicals like benzonitrile today means fewer regrets tomorrow. With practical training and open conversations about risk, everyone has a better shot at making it home safe at the end of every shift.

Understanding Benzonitrile in Everyday Context

Ask a chemistry student about benzonitrile, and the first thing you’ll hear is its formula: C7H5N. That sum represents a molecule made of seven carbon atoms, five hydrogens, and a single nitrogen. Simple at first glance, yet benzonitrile’s story runs far deeper in chemistry labs and industry floors. I’ve seen benzonitrile used as a starting point for crafting more complex molecules, and its value goes beyond just the letters and numbers.

Why Formula Matters: Practical Experience

Every chemist knows naming starts with the structure. Benzonitrile’s formula guides work in the lab and shapes how teams think about safety, storage, and use. For those working with organic synthesis, the formula signals both possibilities and precautions. Mixing up a formula by just a single atom leads to disaster — something I learned quickly in my early days, after a reaction yielded nothing but mess due to a simple oversight. In benzonitrile, the arrangement of those seven carbons into a ring, bonded to a nitrile group, signals how it behaves under heat, what it smells like, and how it dissolves.

Professional standards hinge on those three elements, especially in regulated industries. Research teams rely on the formula to predict boiling points, reactions, and environmental impacts. It shapes troubleshooting: a weird reading on the analyzer led me to double-check the chemical structure, only to catch a supplier’s labeling error just in time.

Making Good Use: Safety, Application, and Knowledge

Anyone handling benzonitrile needs a basic grasp of its formula, because it ties into every risk assessment. I remember my first safety briefing highlighting the way its nitrile group gives off a sharp, bitter almond odor, hinting at possible hazards. Having the formula up front makes hazard communication clear and helps teams set up safe storage and handling: nitriles don’t play nice with acids, and a mistake can trigger off-putting fumes. Firms in pharmaceutical and dye manufacturing count on that formula for further synthesis. Benzonitrile’s core structure shows up in antihistamines, agricultural chemicals, and specialty solvents.

Challenges and Opportunities in Industry Transparency

Formulas keep research transparent. When one lab publishes results, the formula lets others reproduce those findings. That helps science move forward. Still, mistakes sometimes slip through — contaminated lots or incomplete documentation lead to costly recalls. Smart manufacturers verify chemical formulas using spectroscopic tools and reference databases, closing the gap between paperwork and real-world substances.

Better digital record-keeping and investment in quality control tools could shield smaller labs and startups from expensive errors. Training staff to see the connection between a molecule’s formula and its hands-on properties pays off in safety and innovation. Regulatory agencies expect nothing less. It’s a lesson that comes through clearest not from textbooks, but on factory floors, where formulas become the line that divides routine from risky.

Summary: C7H5N’s Significance

Benzonitrile’s chemical formula, C7H5N, does more than label a molecule. It anchors the ways professionals work, protects people, guides research, and supports products that wind up on pharmacy shelves or in dye vats. Formulas, learned through experience and vigilance, help industry stay safe and innovative. Knowing what those numbers mean — and how to check them — stays essential for good science and responsible manufacturing.

Why Benzonitrile Needs Serious Attention

Chemists and lab hands get to know Benzonitrile well. It’s a clear liquid, sharp scent, a bit like almonds with an edge. This isn’t a harmless ingredient—spills irritate skin, its fumes choke up a closed room, and it hits the body hard if handled wrong. I remember someone in my college’s organic lab who left a bottle loose overnight. By morning, the whole bench reeked, and half the class ended up outside with runny eyes. It’s not easy to forget how serious things turn when proper steps fall through the cracks. Mistakes like that stick with you and shape your respect for chemical safety.

The Basics Always Matter

A lot of folks jump straight to fancy gear, but Benzonitrile’s care starts with basics. Solid, amber glass bottles stand out as the best choice. In sunlight, the compound starts to break down, and nobody wants extra byproducts in their process. Clear containers let in UV rays that chip away at purity, sometimes without anybody noticing until a reaction misfires. A sealed screw-top means less chance for vapors to sneak out and cause headaches—literally and for your colleagues too.

Control the Air and Temperature

Air brings in moisture and oxygen. That’s trouble, not just for Benzonitrile but for anything in that cabinet. Water slowly reacts with Benzonitrile, especially if things warm up. Most professional labs run a dry storage cabinet, often with a little desiccant tucked alongside each bottle. Add silica gel if you store bottles anywhere humid. From what I’ve seen, Benzonitrile stays steady under 25°C. I’ve worked in workshops where hot summer days crept up, and the heat built up around stored solvents. Room temperature works but leaning cooler, especially if you have big batches, keeps the risk much lower.

Keep Away from Trouble

Some mistakes stay burned in your mind. I once saw a junior tech stack Benzonitrile near acids and open oxidizers. Big no. Mixing up labeled bottles causes real accidents fast. Acids can set off reactions that release hazardous gases or cause pressure build-ups. Most experienced chemical workers follow this simple move: store Benzonitrile away from acids, bases, oxidizers, and anything that could kick off heat or sparks. Separate shelving, with each chemical type clearly marked, keeps storage safe and the workflow predictable.

Labels: Clear, Honest, Complete

A faded label spells trouble. Every Benzonitrile container in a good lab carries a clear label: the name, concentration, and date received. If you decant, the new bottle gets the same treatment. I learned early on, from a supervisor who’d seen too many close calls, that honesty on labels saves time and prevents mistakes. If something spills or a fire breaks out, nobody’s wondering what’s in the container.

Training and Routine Checks Save Hassle

Most storage accidents crop up because someone skipped a step or never saw a proper handover. I keep a storage checklist up, marking routine checks for leaks, expired stock, and broken bottles. Even used solvents go straight to a waste bottle, away from possible spills. If you’re managing a workspace, regular safety training—real hands-on stuff, not just posters on the walls—keeps everyone sharp. Sharing stories from personal experience, the ones that hit close to home, help new staff grasp the real risks and not just the rules.

Short Guide for Solid Storage

- Store in amber, airtight glass bottles- Keep away from direct sunlight and heat- Use a dry, well-ventilated storage area- Separate from acids, oxidizers, and bases- Label clearly and keep logs updated- Schedule regular safety checks and training

Benzonitrile Demands Respect

Anyone who’s spent hours over a lab bench has at some point crossed paths with chemicals that bite back the moment you get careless. Benzonitrile fits right into that group. Colorless, almond-scented, and fairly common in organic synthesis, this liquid doesn’t mess around. Skin exposure, inhalation, accidental spills—each of these can lead to headache, drowsiness, or a real case of chemical burns. I’ve learned to put my guard up even when I’m just opening a fresh bottle.

Goggles and Gloves Aren’t Optional

Early in my chemistry days, I underestimated how quickly benzonitrile can penetrate nitrile gloves. Standard-issue latex won’t cut it. Always grab a thick pair—something like butyl or neoprene gloves. Don’t just swap out gloves at the end of your shift; check for degradation before each use. Eye protection matters just as much. I’ll never forget the sting of a tiny splash near my eye during a rushed transfer. Splash goggles trump regular safety glasses, every time.

Keep Air Moving

Inhalation risk won’t always shout its presence. Warm weather, tight spaces, lengthy syntheses—benzonitrile vapor sneaks into the air. Good ventilation makes accidents far less likely. A well-kept fume hood remains the safest option. Crack that sash down close, make sure the airflow feels steady, and always double-check the airflow monitor before weighing or pouring. Even a small fan isn’t a real substitute; it just pushes vapor around and gives a false sense of security.

Smarter Storage Choices

Benzonitrile stores best away from sunlight and heat. I stick mine in a locked flammables cabinet, never in regular shelving or next to oxidizing agents. The container caps deserve just as much attention—not half-tight, never with visible crust or damage. A loose cap means vapor leaks, which leads to off smells, corrosion, and long-term health risks. Labeling gets overlooked in busy labs, but a clear, chemical-resistant label with hazard symbols sets everyone up for safe handling.

Solid Emergency Routines

Complacency leads to mistakes. Even with the cleanest workflows, spills and splashes creep in from time to time. I run a quick emergency drill at least once a month—where’s the eyewash, who grabs the spill kit, how long to flush skin. Fast response can mean the difference between a minor irritation and an ER visit. Know your Material Safety Data Sheet by heart, or at least keep a paper copy on hand. Russell from my old lab once delayed washing his hands after a mixed solvent spill. He ended up with blisters lasting weeks.

Don’t Skip the Basics

To sum it up, nobody handling benzonitrile can afford shortcuts. Protective gear, good ventilation, safe storage, and a real plan for emergencies—these steps exist for a reason. The hazards stick around no matter how many times you’ve used the chemical. Respecting them makes every lab worker safer and keeps dangerous incidents off the front page. With toxic substances like benzonitrile, the right habits aren’t just helpful. They’re essential.

| Names | |

| Preferred IUPAC name | benzonitrile |

| Other names |

Benzenecarbonitrile

Phenyl cyanide Cyanobenzene |

| Pronunciation | /ˌbɛn.zəˈnaɪ.trɪl/ |

| Preferred IUPAC name | benzonitrile |

| Other names |

Benzenecarbonitrile

Phenyl cyanide Cyanobenzene Phenylnitrile |

| Pronunciation | /bɛnˈzoʊnaɪtraɪl/ |

| Identifiers | |

| CAS Number | 100-47-0 |

| Beilstein Reference | 605945 |

| ChEBI | CHEBI:17718 |

| ChEMBL | CHEMBL545 |

| ChemSpider | 969 |

| DrugBank | DB03762 |

| ECHA InfoCard | 100.013.225 |

| EC Number | 202-841-1 |

| Gmelin Reference | 778 |

| KEGG | C00819 |

| MeSH | D001587 |

| PubChem CID | 7487 |

| RTECS number | CU1400000 |

| UNII | YXFVVABEGXRONW-UHFFFAOYSA-N |

| UN number | 1994 |

| CompTox Dashboard (EPA) | DTXSID0025947 |

| CAS Number | 100-47-0 |

| Beilstein Reference | 635542 |

| ChEBI | CHEBI:18109 |

| ChEMBL | CHEMBL: CHEMBL1079 |

| ChemSpider | 970 |

| DrugBank | DB03714 |

| ECHA InfoCard | ECHA InfoCard: 100.003.240 |

| EC Number | 202-349-0 |

| Gmelin Reference | 3779 |

| KEGG | C01324 |

| MeSH | D001570 |

| PubChem CID | 8109 |

| RTECS number | CU1400000 |

| UNII | F8K8C0O5PZ |

| UN number | UN1994 |

| Properties | |

| Chemical formula | C7H5N |

| Molar mass | 103.12 g/mol |

| Appearance | Colorless to pale yellow liquid |

| Odor | almond-like |

| Density | 1.01 g/mL at 25 °C (lit.) |

| Solubility in water | Moderately soluble |

| log P | 1.60 |

| Vapor pressure | 0.38 mmHg (25°C) |

| Acidity (pKa) | 25.0 |

| Basicity (pKb) | -10.0 |

| Magnetic susceptibility (χ) | -54.5·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.528 |

| Viscosity | 1.23 mPa·s (25 °C) |

| Dipole moment | 4.18 D |

| Chemical formula | C7H5N |

| Molar mass | 103.12 g/mol |

| Appearance | Colorless to pale yellow liquid |

| Odor | almond-like |

| Density | 1.01 g/mL at 25 °C (lit.) |

| Solubility in water | 6.9 g/100 mL (25 °C) |

| log P | 1.56 |

| Vapor pressure | 0.5 mmHg (at 25 °C) |

| Acidity (pKa) | 23.4 |

| Basicity (pKb) | 7.94 |

| Magnetic susceptibility (χ) | -48.8e-6 cm³/mol |

| Refractive index (nD) | 1.525 |

| Viscosity | 1.24 mPa·s (25 °C) |

| Dipole moment | 4.18 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 170.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | 119.0 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3254 kJ mol⁻¹ |

| Std molar entropy (S⦵298) | 176.9 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | +138.5 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3261 kJ·mol⁻¹ |

| Hazards | |

| Main hazards | Toxic if swallowed, in contact with skin or if inhaled; causes skin and eye irritation; harmful to aquatic life. |

| GHS labelling | GHS02, GHS07, GHS09 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H226, H301, H311, H331, H373 |

| Precautionary statements | P210, P261, P264, P271, P280, P301+P310, P304+P340, P312, P330, P403+P233, P405, P501 |

| NFPA 704 (fire diamond) | 3-2-0 |

| Flash point | 86 °C |

| Autoignition temperature | 686 °C |

| Explosive limits | Explosive limits: 1.4–8.0% |

| Lethal dose or concentration | LD50 oral rat 640 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat LD50 = 640 mg/kg |

| NIOSH | CD9450000 |

| PEL (Permissible) | 5 ppm |

| REL (Recommended) | 50.0 ppm |

| IDLH (Immediate danger) | 200 ppm |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H226, H301, H311, H331, H373 |

| Precautionary statements | P210, P261, P280, P301+P310, P303+P361+P353, P304+P340, P305+P351+P338, P312, P330, P403+P233, P501 |

| NFPA 704 (fire diamond) | 1-2-0-☠ |

| Flash point | 86 °C (closed cup) |

| Autoignition temperature | 660 °C |

| Explosive limits | Explosive limits: 1.4–7.1% |

| Lethal dose or concentration | LD50 oral rat 640 mg/kg |

| LD50 (median dose) | LD50 (median dose) of Benzonitrile: 640 mg/kg (oral, rat) |

| NIOSH | CN9100000 |

| PEL (Permissible) | 5 ppm |

| REL (Recommended) | 0.15 mg/L |

| IDLH (Immediate danger) | 200 ppm |

| Related compounds | |

| Related compounds |

Benzyl cyanide

Phenylacetylene Aniline Benzaldehyde Benzoic acid |

| Related compounds |

Phenylacetylene

Benzyl cyanide Cyanogen Acetonitrile Benzylamine |