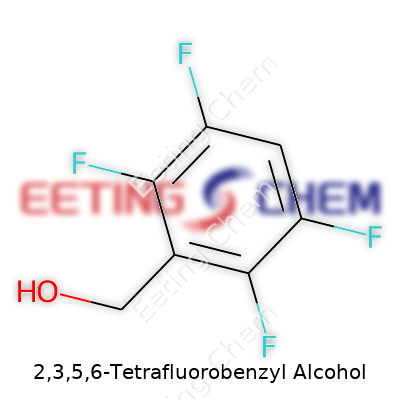

2,3,5,6-Tetrafluorobenzyl Alcohol: An In-Depth Commentary

Historical Development

Back in the days when organofluorine chemistry started gaining momentum, 2,3,5,6-tetrafluorobenzyl alcohol joined the roster of interesting building blocks. The discovery of polyfluorinated aromatics in the mid-20th century came from the continued pursuit for specialty molecules, especially those with unique electronic and metabolic profiles. The need for fine-tuned synthetic intermediates led folks in research labs to focus on increasingly selective halogenated derivatives, marking out 2,3,5,6-tetrafluorobenzyl alcohol as a key intermediate for both academia and industry. Early synthetic routes tended to rely on harsh reagents and low yields. Over the decades, new fluorination techniques emerged, opening more practical paths to this alcohol and its relatives. As methods for controlling regioselectivity improved, chemists started seeing more reliable access, shifting this compound from a rare curiosity to a regular staple in some advanced chemical toolkits.

Product Overview

2,3,5,6-Tetrafluorobenzyl alcohol comes across as a specialty aromatic alcohol with four fluorine atoms sitting on the benzene ring, leaving only the para position untouched. That dense fluorine substitution isn’t just for show; it gives the molecule a special combination of chemical stability and reactivity that plays well in downstream chemistry. The benzyl alcohol functional group allows chemists to plug it into a wide spectrum of organic transformations. Because of its niche properties, this compound mainly finds demand among research groups and process chemists working on pharmaceuticals, agrochemicals, and materials science. Unlike mainstream solvents or simple pesticides, this isn’t a bulk product. It’s more like a detailed tool, waiting for someone with a specific job in mind. From my own bench work, few things test the patience of glassware like perfluorinated aromatics, but that’s also what makes them valuable for challenging synthesis.

Physical & Chemical Properties

On the physical properties side, 2,3,5,6-tetrafluorobenzyl alcohol usually appears as a colorless to pale yellow liquid or solid, depending on room temperature and purity. Its melting and boiling points reflect the strong influence of those electronegative fluorine atoms, which lower intermolecular attractions but raise volatility. The compound is only sparingly soluble in water, as the fluorine ring doesn’t play well with hydrogen bonding, but shows good miscibility with polar organic solvents. Chemically, it carves out a niche because the benzyl alcohol group is more reactive than a regular phenol, yet the ring is less prone to oxidative decomposition, all thanks to the electron-withdrawing power of those fluorines. This stability-to-reactivity balance lets researchers push harder on transformation conditions without risking runaway side reactions.

Technical Specifications & Labeling

Many vendors offer 2,3,5,6-tetrafluorobenzyl alcohol in lab-scale quantities ranging from a few grams to several hundred grams. Product datasheets commonly include purity levels, with 97–99% being standard through chromatography or NMR. Labels carry UN hazard information, batch numbers, and storage guidelines. Sensitive to light and moisture, it benefits from amber bottles and cool storage, although it doesn’t demand cryogenic conditions. The usual set of hazard symbols and statements concerning skin and eye irritation come along for the ride, along with careful documentation for transport under REACH or similar regulatory frameworks. From ordering this compound myself, reliable suppliers tend to run comprehensive analytical checks, making trace residue concerns pretty rare.

Preparation Method

Organic chemists build 2,3,5,6-tetrafluorobenzyl alcohol by starting with a suitably substituted tetrafluorotoluene or similar aromatic precursor. The key step involves selective side-chain oxidation or functionalization, which turns the methyl group on the ring into the primary alcohol. Electrochemical fluorination and modern catalytic fluorination make it possible to control both the degree and position of fluorine atoms. Another method involves sequential halogen exchange, often starting from tetrahalobenzenes, followed by nucleophilic aromatic substitution, protecting group manipulation, and finally reduction or oxidation to install the alcohol. These routes can get complicated fast — both in terms of reagent handling and waste stream management. In my own time in the lab, using robust intermediates for the ring system, followed by gentle final deprotection, trimmed lots of wasted effort and helped suppress unwanted side products.

Chemical Reactions & Modifications

The benzyl alcohol group offers a handle for further transformations — oxidation leads to the corresponding aldehyde or acid, while etherification and esterification open doors to a vast family of derivatives. Silylation of the alcohol also protects it for multistep synthesis, giving process chemists options for more complex molecules downstream. The fluorinated aromatic core changes the typical reaction rates, blocking unwanted side reactions and shifting selectivity. For example, electrophilic aromatic substitution becomes nearly impossible due to the fluorines, but nucleophilic aromatic substitutions remain possible. Coupling chemistry with other aryl partners, or using the alcohol for SN2 type reactions, shows up in pharma R&D all the time. I’ve often adapted protocols to harness this stability when working on new bioisosteres or probe molecules, where metabolic resistance and unique activity profiles are crucial.

Synonyms & Product Names

2,3,5,6-Tetrafluorobenzyl alcohol isn’t short on aliases: it’s known by its CAS number 1783-56-6, alongside names like TFB alcohol, tetrafluorobenzyl alcohol, and (2,3,5,6-tetrafluorophenyl)methanol. Sometimes, chemical catalogs list it with company-specific codes or abbreviations. This isn’t just pedantry; tracking these synonyms avoids mistakes in ordering or regulatory reporting. Years ago, I saw an order misfire where a team received a different tetrafluorinated benzyl alcohol, setting back a whole project by several weeks — a reminder that accuracy with names and numbers goes deeper than paperwork.

Safety & Operational Standards

Handling tetrafluorinated benzylic compounds demands a bit more rigor compared to typical laboratory materials. Eye and skin contact lead to irritation, and inhalation of vapors should be minimized. Standard PPE suffices for short-term work, but good ventilation and glove use remain essential. Waste handling requires respect due to the compound’s persistence and toxicity potential, flagged by environmental regulations in most jurisdictions. FD-approved secondary containment and clear labeling lessen the risk of accidental exposure. Emergency procedures for splashes or spills stay fairly standard, focusing on thorough washing and medical evaluation. Having spent years in both synthetic and analytical settings, I learned to never take shortcuts with these kinds of compounds. Attention to detail keeps accidents and exposures from disrupting good research.

Application Area

Most requests for 2,3,5,6-tetrafluorobenzyl alcohol end up serving chemical synthesis — both as an intermediate for more complex targets and as a probe molecule for biological and materials testing. The pharmaceutical industry sometimes pampers this compound for the unique way its aromatic system boosts metabolic stability in drug candidates. Agrochemical researchers use it to design crop protection agents with less environmental persistence. In material science, the alcohol’s reactivity allows it to bolt onto complex polymers, granting specialty plastics or coatings new optical and electronic properties. Analytical chemistry benefits too: it occasionally appears in derivatization protocols for improved detection sensitivity. My experience collaborating with med-chem teams showed it’s rarely the center of attention but often a silent workhorse enabling later breakthroughs.

Research & Development

Recent academic and industry research keeps looking for new ways to use and make 2,3,5,6-tetrafluorobenzyl alcohol. Efforts focus on methodology, such as improving selectivity for its preparation or customizing downstream transformations. Some groups pursue novel catalysts that cut costs and shrink waste, especially with the environmental footprint of fluorinated byproducts in mind. In pharmaceutical discovery, efforts track how these fluorinated systems affect metabolic fate and binding selectivity, with computational chemistry taking a bigger role in predicting the performance of these motifs. Some startups are plugging perfluorinated aromatics into newer materials, like OLEDs or specialty membranes, hoping to hit a sweet spot between performance and manufacturability. At conferences and in journals, researchers keep jockeying for new twists — the work never really stops.

Toxicity Research

Toxicological profiles for 2,3,5,6-tetrafluorobenzyl alcohol point to mild-to-moderate acute toxicity for mammals, mostly by ingestion or prolonged exposure. Chronic exposure data remains thin, but the structure’s fluorination hints at persistence both in body and environment. Animal studies suggest low rates of bioaccumulation compared to perfluorinated alkyl substances, yet regulators keep a watchful eye on any persistent organic chemical. In the lab, incidents involving fluorinated benzylic compounds are rare but get full investigation, as even low-level skin contact causes irritation or dermatitis. Safe disposal matters since legislation in the U.S., EU, and Japan places a premium on responsible handling and destruction of organofluorine waste. From my safety training, protocols evolve quickly with any whispers of new toxicity signals, always erring on caution.

Future Prospects

The path forward for 2,3,5,6-tetrafluorobenzyl alcohol sits at the intersection of sustainable synthesis, regulatory compliance, and application-driven demand. The drive for more efficient and environmentally friendly fluorine chemistry means greener synthetic options will shape the next generation of production. At the same time, regulatory tides on fluorinated organic compounds keep researchers alert to shifting standards. New uses in diagnostics, smart coatings, or as building blocks for imaging agents in nuclear medicine could offer growth areas. The community benefits from cross-talk between academia and industry, pushing innovation while ironing out risks. Every time new technologies emerge in fluorine chemistry, the odds shift toward finding more value in this molecule both in lab and in application.

A Closer Look at a Unique Chemical

Focusing on 2,3,5,6-tetrafluorobenzyl alcohol opens a window into modern chemistry, especially when you think about how often fluorine shows up in new materials. Chemists typically turn to this compound because it blends reactivity with stability. A few years ago during an internship, I saw chemists use this molecule in the synthesis of building blocks for pharmaceuticals. Watching them, I realized that these specialized alcohols often feature in things we encounter every day, even though most folks have never heard their names.

Building Blocks for Pharmaceuticals and Beyond

For drug development, the fluoroaromatic groups make a big difference. Adding fluorine atoms to a molecule can slow down metabolic breakdown, which can give medicines longer shelf life and enhance their ability to reach the right place in the body. Companies often start with intermediates like 2,3,5,6-tetrafluorobenzyl alcohol because the structure allows for precise chemical modifications. That small tweak in the lab—switching a hydrogen for a fluorine—can give a major boost in blocking an enzyme or passing through cell walls. It’s this kind of tinkering that made several antiviral drugs successful. Some research out of Germany in 2021 highlighted how tetrafluorinated benzyl alcohols serve as scaffolds for new therapies.

Advanced Materials Step Up with Fluorinated Compounds

It’s not just pills and potions. Tech companies rely on the toughness and chemical resistance that fluorinated compounds deliver. A layer of these chemicals can keep sensors safe from moisture or corrosion. In one project I followed in a specialty polymers plant, adding tetrafluorobenzyl alcohol as a starting piece helped create coatings that survived weeks of salt spray without flinching. Makers of electronics don’t only care about durability; they also tune electrical performance with these compounds. Field-effect transistors, batteries, and display technology all draw on the steady hand of fluorine chemistry, so the building blocks behind them, like 2,3,5,6-tetrafluorobenzyl alcohol, become invaluable.

Lab Techniques Depend on Smart Chemistry

Analytical labs have also found a soft spot for this molecule. To detect trace contaminants or reveal hidden molecules in biological samples, researchers will transform a compound into a more detectable version, often called a “derivative.” Tetrafluorobenzyl alcohol plays its role here. Its reputation as a reliable derivatizing agent stems from its reactivity with carboxylic acids, amines, and even thiols. The result? Cleaner, sharper peaks in mass spectrometry analysis. Speaking with colleagues in food safety, I’ve learned that this approach can unmask tiny residues in imported produce, making our food supply a bit safer.

Risks and Responsible Handling Matter

No one should overlook the risks tied to handling fluorinated chemicals. Manufacturing and working with 2,3,5,6-tetrafluorobenzyl alcohol demands respect for proper ventilation and protective gear. Exposure should never be brushed off; studies point to the persistent nature of fluorinated atoms once they reach the environment. Industry is moving toward improved guidelines on disposal and containment. In my own practice, double-checking waste procedures and encouraging better lab habits came after realizing the long tail of PFAS pollution stories.

Where Regulations and Innovation Intersect

Policies call for close scrutiny of fluorinated substances, driven by environmental worries and concern for human health. Manufacturers must now track their supply chains and, in some regions, report tonnages or intent to use these materials. Scientific innovation has already started to chase biodegradable alternatives, plus ways to engineer less persistent molecules while delivering the same performance. The hope rests with a new generation of chemists who mix curiosity with responsibility.

Unpacking a Complex Name

Hearing “2,3,5,6-Tetrafluorobenzyl Alcohol” might make some folks take a step back. Once you start breaking it down, the picture gets clearer. Start with the core: benzyl alcohol. Take a benzene ring, swap one hydrogen for a hydroxymethyl group (–CH2OH), and you’ve got benzyl alcohol. Add four fluorine atoms on the ring, specifically at the 2, 3, 5, and 6 positions. We can count up the atoms: benzene brings six carbons and six hydrogens, the alcohol adds another carbon, two hydrogens, and an oxygen, but four hydrogens on the ring get replaced by fluorines.

Counting Atoms for the Formula

Let’s tally up. The benzene ring: C6H6. Making it benzyl alcohol, swap a hydrogen on the ring for a –CH2OH group, which is one carbon, two hydrogens, and one oxygen. That makes C7H8O. Subtract four hydrogens, since the fluorine atoms boot them off, and add four fluorines. What’s left is C7H4F4O.

The Significance of the Molecular Formula

A single letter or number in a chemical formula says a lot. C7H4F4O means seven carbons tied together, four hydrogens, four fluorines, and one oxygen. A formula this explicit gives researchers a map to the molecule’s guts. With fluorine atoms lined up on the benzene ring, this isn’t just about naming – it changes everything from chemical reactivity to how this stuff behaves in a lab. Fluorinated compounds often show increased thermal stability, higher resistance to chemical breakdown, and unique interactions in electronic and pharmaceutical research.

In my own time spent working with fluorinated aromatics, I saw firsthand how those little swaps on a benzene ring can mean the difference between a compound that dissolves in water and one that avoids it altogether. The presence of fluorine atoms often makes molecules more lipophilic, less likely to break down, and more stable under heat and light. That stability comes in handy for designing materials and drugs that need to last and perform under harsh conditions.

Value in Research and Industry

2,3,5,6-Tetrafluorobenzyl Alcohol stands out for more than just its tongue-twister of a name. Chemical companies and university labs look to molecules like this as building blocks for bigger, sometimes life-saving, molecules. You’ll spot them in the paths toward agrochemicals, pharmaceutical ingredients, and advanced polymers. The unique chemical properties of highly fluorinated structures let researchers tweak solubility, boost bioavailability, or make new coatings and adhesives that shrug off moisture and corrosion.

Challenges and Looking Forward

Handling and producing multi-fluorinated compounds brings challenges. Sourcing the raw materials, staying safe in the lab, and dealing with waste all call for smart practices and strong oversight. The world’s slowly waking up to environmental side effects of persistent fluorinated compounds—many don’t break down easily in nature. Finding cleaner ways to make and use them matters for the health of communities and the planet.

Teams in chemical research and green chemistry are finding routes around traditional high-energy, high-waste processes. Catalysts that cut down on hazardous byproducts and recycling scrap streams aren’t just wishful thinking; they’re changing the way these molecules hit the market. The goal is to keep delivering the remarkable benefits that compounds like 2,3,5,6-Tetrafluorobenzyl Alcohol offer, with fewer strings attached.

Connecting Molecular Details with Real-World Impact

Understanding the formula C7H4F4O is more than textbook knowledge. For chemists, it means a toolbox for innovation, proven by everyday products that come out tougher, safer, and more effective. By keeping an eye on new production methods and environmental effects, the true promise of this molecule can carry through, from the lab bench to the wider world.

Understanding What It Is

2,3,5,6-Tetrafluorobenzyl alcohol doesn't turn up often in daily conversation. This compound plays a supporting role in chemical syntheses, especially for pharmaceuticals and advanced materials. Anyone handling it probably works in a lab with gloves, goggles, and at least some idea of what’s on the label. But the average person likely doesn’t know if this stuff’s downright dangerous or just another odd chemical name in a long list of lab stocks.

What Actual Science Says

The fluorine atoms attached to the benzyl group change things quite a bit compared to regular alcohols or benzyl alcohol itself. In general, compounds with many fluorine atoms can act slippery and hard for the body to break down—that’s part of why forever chemicals (PFAS) cause so much debate in environmental circles. If you dig into the limited data available on this alcohol, you’ll find that safety sheets typically slap on the same warnings that show up for many lab chemicals: Don’t breathe the vapor, don’t get it on your skin, don’t swallow it. That raises a flag, but not a red one waving like you’d see for things such as benzene or chloroform, both much older and more researched nasties.

Personal Experience in a Research Lab

I spent years around organic labs, and substances like this generally show up in small glass bottles with a maze of hazard labels. Nobody in our lab treated these materials casually—if something splashes, even just a drop, everyone’s on edge until safety practices kick in. We didn’t find that 2,3,5,6-Tetrafluorobenzyl alcohol gave off obvious fumes or weird smells, but that might only mean a proper fume hood did its job. What stands out, though, is that even without major acute risks, repeated contact with fluorinated organic compounds isn't something you want to gamble with.

Why Caution Matters

Breathing in or absorbing substances with lots of fluorinated groups can stress the liver and kidneys. People working with these chemicals sometimes show symptoms over years, not days. Even though published data doesn’t pin down 2,3,5,6-Tetrafluorobenzyl alcohol as a prime suspect for toxicity, its molecular family suggests caution. Researchers have learned over decades that exposure to similar chemicals may lead to trouble nobody predicted when the compound first entered the market—just look at the slow recognition of PFAS-related issues.

The Right Kind of Protection

Companies using this compound should provide serious personal protective equipment—no shortcuts. Anyone handling the substance needs clear training, especially about what to do if there’s a spill. Waste disposal ranks high here as well: Putting it in the sink or general trash only spreads a molecule that can linger in water or soil, sticking around much longer than science once guessed. Regulators in both the US and EU keep an eye on new fluorinated chemicals for good reason, even if individual studies don’t call something acutely toxic. It makes sense to channel that concern into company policies and lab protocols, not just cross fingers and hope for the best. As green chemistry searches for replacements, anything with multiple fluorines in its framework draws special notice.

Practical Steps Forward

If you work around this substance, keep gloves and goggles on, use fume hoods, and avoid open containers. If you manage a workplace or university lab, update safety briefings to include current findings on fluorinated organics. Clear labeling and strict waste protocols help prevent headaches down the road—whether lawsuits, illnesses, or environmental messes. Newer studies might one day sharpen the risk profile for 2,3,5,6-Tetrafluorobenzyl alcohol, but smart habits and proactive policies show respect for both worker health and long-term sustainability.

Understanding the Risks

2,3,5,6-Tetrafluorobenzyl alcohol isn’t your typical household chemical. I’ve encountered it in research settings, particularly in labs focused on pharmaceutical or advanced materials chemistry. The compound packs a punch with its fluorinated rings—making it useful, but also a little more unpredictable than less exotic alcohols. People handling it may not always think about safety first, but direct exposure to the skin or inhalation brings a risk of irritation or even longer-term health problems depending on the exposure level.

Storing for Stability and Safety

Temperature control makes a big difference here. Most lab teams keep fluorinated alcohols around room temperature, away from any source of heat. Even a sunny window can shift the stability profile. Fluctuating temperatures encourage decomposition or slow reactions with container materials that aren’t designed for chemical work. I stick to cool, shaded storage—think lockable chemical cabinets shielded from temperature swings.

Container choice matters. Glass, especially borosilicate, gives better peace of mind than plastic for this compound. Tetrafluorobenzyl alcohol can leach or gradually degrade cheaper plastics, especially if someone grabs any bottle off the shelf without reading the label. Well-sealed containers stop vapors escaping, cut down on evaporation, and protect everyone in shared spaces.

Some solvents and chemicals in a laboratory don’t play well together. Mixing storage, even by accident, risks contamination or a sneaky chemical reaction. I have always separated fluorinated alcohols from oxidizers and acids. A close call in a grad school lab—where a mislabeled bottle ended up near strong oxidizers—showed how quickly a slip-up could spark an emergency. Shelving and inventory logs keep the problem in check.

Labeling: More Than Just a Sticker

I’ve opened fridges and cabinets and found bottles with marker-scrawled labels, or worse, peeling tape. Proper labeling, not just the name but concentration, date received, and hazard information, makes everyday work safer and smarter. Any bottle missing a clear label gets flagged for disposal in my workspace. This habit saves hassle if someone in the team swaps roles, and keeps emergency responders informed in a pinch.

Protection for the People

Personal experience taught me not to underestimate fumes, even with “benign” alcohols. Direct exposure sometimes leads to skin or respiratory irritation. Gloves—nitrile, never latex—plus splash goggles form my go-to gear. Good ventilation, like a fume hood, beats relying on an open window or basic vent fans, especially if handling more than just a few milliliters at a time.

Smart Policies Prevent Mistakes

Labs and workplaces using 2,3,5,6-tetrafluorobenzyl alcohol benefit from clear, easy-to-follow chemical hygiene rules. Training all users to check labels, log chemical movement, and report damaged containers or leaks keeps accidents rare and people safer. Facilities with strong safety records pair practical storage steps with a culture of speaking up about risks.

Chemical safety demands more than checklists—it builds on habits, shared responsibility, and planning for unexpected moments. The goal always stays the same: protect the people, preserve the compound, and keep science on track.

The Look and Feel of 2,3,5,6-Tetrafluorobenzyl Alcohol

Open a bottle of 2,3,5,6-Tetrafluorobenzyl Alcohol and you won’t see anything particularly fancy. The compound pours mostly as a clear, colorless to pale yellow liquid. Every batch I’ve worked with gives off a slight odor, not as harsh as some solvents but definitely recognizable—it reminds you this isn’t something you’d mistake for water in the lab. Those with sharp eyes might notice that if left exposed, it can darken just a bit, especially when sitting out for a while under normal room lighting.

Purity: What Matters in a Lab or a Factory

Most researchers want their chemicals as clean as possible. With 2,3,5,6-Tetrafluorobenzyl Alcohol, it’s all about the purity. Many chemical suppliers guarantee at least 97% or 98%, and some even hit that sweet spot above 99%. The difference between a 97% and a 99% batch might seem tiny, but for anyone running exacting synthetic work, those impurities can completely ruin a chemical reaction. Impurities often show up as tiny traces—extra peaks in an HPLC test, some residue left during distillation, or an unusual streak when running a TLC plate.

I remember trying to build a fluorinated building block for a drug project, and every percentage of purity counted. A slightly lower grade of this alcohol once left us chasing a ghost signal in our NMR spectra for days. Only later did we realize it was a contamination issue—the bottle hadn’t been sealed tightly enough after the last use. That lesson stuck with me: purity can make or break a whole week’s worth of effort, especially when working at the scale of milligrams or a few grams.

Handling Challenges and Solutions

Nobody loves spending a premium on a reagent just to watch it degrade due to sloppy storage. This alcohol isn’t particularly fragile, but exposure to air, moisture, or light for long hours doesn’t do it any favors. We always kept ours sealed tightly in amber glass, in a cool lab cabinet. Safety data sheets recommend avoiding skin contact and inhalation, so gloves and goggles are more than formality.

Synthetic chemists often have to purify reagents themselves if the supplier’s specs don’t cut it. Simple distillation under reduced pressure works most of the time. Add a little activated charcoal if the solution’s looking yellow, and you pick up most colored byproducts or trace oxidation products. Sometimes a quick pass through a silica plug finishes the job. It’s all about knowing your tools—having access to a decent rotary evaporator and watching your solvent selection helps keep things clean.

Why Purity and Appearance Aren’t Just Cosmetic

The appearance of this alcohol serves as a quick check, but a clear sample doesn’t guarantee real purity. Color changes or cloudiness often point to breakdown products, contamination, or reactions with air. Chemists lean heavily on analytical tools—NMR, IR, GC-MS, and titration—to confirm purity, especially in regulated industries. In pharmaceuticals, a contaminated solvent or reagent could mean costly recalls or even patient harm down the road. In research, it can send a whole project in the wrong direction.

No matter the scale, purity and appearance will always hold value far beyond the cosmetic. Proper storage, supplier care, and analytical vigilance keep this fluorinated alcohol doing its job, without introducing new headaches into the project.

| Names | |

| Preferred IUPAC name | 2,3,5,6-tetrafluorophenylmethanol |

| Other names |

2,3,5,6-Tetrafluorobenzyl alcohol

Tetrafluorobenzyl alcohol 2,3,5,6-Tetrafluoro-1-(hydroxymethyl)benzene |

| Pronunciation | /ˌtɛ.trəˌflʊə.rəˈbɛn.zɪl ˈæl.kə.hɒl/ |

| Preferred IUPAC name | 2,3,5,6-tetrafluorophenylmethanol |

| Other names |

2,3,5,6-Tetrafluorobenzyl alcohol

Benzyl alcohol, 2,3,5,6-tetrafluoro- 2,3,5,6-Tetrafluoro-1-(hydroxymethyl)benzene |

| Pronunciation | /ˌtɛ.trə.fluː.rəˈbɛn.zɪl ˈæl.kə.hɒl/ |

| Identifiers | |

| CAS Number | [345-13-1] |

| Beilstein Reference | 80020 |

| ChEBI | CHEBI:131377 |

| ChEMBL | CHEMBL510791 |

| ChemSpider | 127530 |

| DrugBank | DB08296 |

| ECHA InfoCard | 03a6b7e6-e748-411d-9c53-6e7a0a1d1b9b |

| EC Number | 209-393-6 |

| Gmelin Reference | 63174 |

| KEGG | C19430 |

| MeSH | D058186 |

| PubChem CID | 69538 |

| RTECS number | ZE5950000 |

| UNII | L897D8P6DS |

| UN number | UN3272 |

| CompTox Dashboard (EPA) | DTXSID3049054 |

| CAS Number | [373-11-3] |

| Beilstein Reference | 1718731 |

| ChEBI | CHEBI:85365 |

| ChEMBL | CHEMBL137597 |

| ChemSpider | 219922 |

| DrugBank | DB08360 |

| ECHA InfoCard | 03dbea6d-e7e4-4a8b-8c6b-ee5e1938b8e2 |

| EC Number | 205-588-6 |

| Gmelin Reference | 72656 |

| KEGG | C19597 |

| MeSH | D017240 |

| PubChem CID | 122081 |

| RTECS number | DI8642000 |

| UNII | 5Q6UOOM1BY |

| UN number | UN1993 |

| CompTox Dashboard (EPA) | DTXSID3049153 |

| Properties | |

| Chemical formula | C7H4F4O |

| Molar mass | 192.12 g/mol |

| Appearance | Colorless liquid |

| Odor | Odorless |

| Density | 1.49 g/cm³ |

| Solubility in water | Slightly soluble |

| log P | 1.6 |

| Vapor pressure | 0.3 mmHg (20°C) |

| Acidity (pKa) | 12.4 |

| Basicity (pKb) | pKb > 14 |

| Magnetic susceptibility (χ) | -56.8·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.427 |

| Viscosity | 41 cP (20°C) |

| Dipole moment | 1.6 D |

| Chemical formula | C7H4F4O |

| Molar mass | 180.10 g/mol |

| Appearance | Colorless liquid |

| Odor | Odorless |

| Density | 1.49 g/cm³ |

| Solubility in water | insoluble |

| log P | 1.8 |

| Vapor pressure | 0.2 mmHg (25 °C) |

| Acidity (pKa) | 15.3 |

| Basicity (pKb) | pKb ≈ 15 (estimated, very weak base) |

| Refractive index (nD) | 1.418 |

| Viscosity | 1.03 cP (25°C) |

| Dipole moment | 2.62 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 330.8 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -686.6 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -2296 kJ/mol |

| Std molar entropy (S⦵298) | 312.4 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -715.7 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1886 kJ/mol |

| Hazards | |

| Main hazards | Harmful if swallowed. Causes skin irritation. Causes serious eye irritation. May cause respiratory irritation. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H302, H312, H332, H319 |

| Precautionary statements | P210, P261, P280, P305+P351+P338, P304+P340, P312, P337+P313 |

| Flash point | Flash point: 113°C |

| Autoignition temperature | 350 °C |

| LD50 (median dose) | Oral rat LD50: >2000 mg/kg |

| PEL (Permissible) | PEL: Not established |

| REL (Recommended) | No REL established |

| IDLH (Immediate danger) | NIOSH has not established an IDLH value for 2,3,5,6-Tetrafluorobenzyl Alcohol. |

| Main hazards | Harmful if swallowed. Causes skin irritation. Causes serious eye irritation. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H302, H315, H319, H335 |

| Precautionary statements | P210, P260, P280, P301+P312, P305+P351+P338, P337+P313 |

| Flash point | Flash point: 110°C |

| Autoignition temperature | 400 °C |

| LD50 (median dose) | LD50 (median dose): Oral rat LD50 >2000 mg/kg |

| PEL (Permissible) | PEL: Not established |

| REL (Recommended) | 10 mg/m3 |

| Related compounds | |

| Related compounds |

Benzyl alcohol

2,3,5,6-Tetrafluorotoluene 2,3,5,6-Tetrafluorobenzaldehyde Pentafluorobenzyl alcohol 2,3,4,5,6-Pentafluorobenzyl alcohol |

| Related compounds |

2,3,5,6-Tetrafluorotoluene

2,3,5,6-Tetrafluorobenzaldehyde 2,3,5,6-Tetrafluorobenzoic acid Hexafluorobenzyl alcohol Benzyl alcohol |